.

.

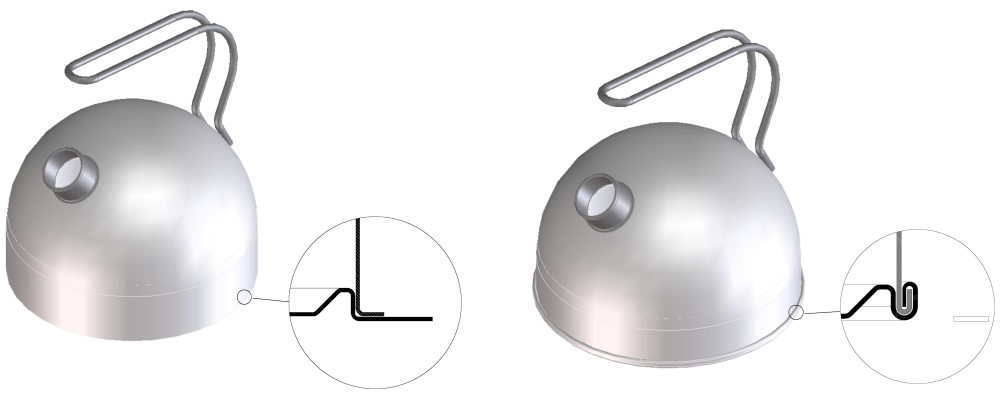

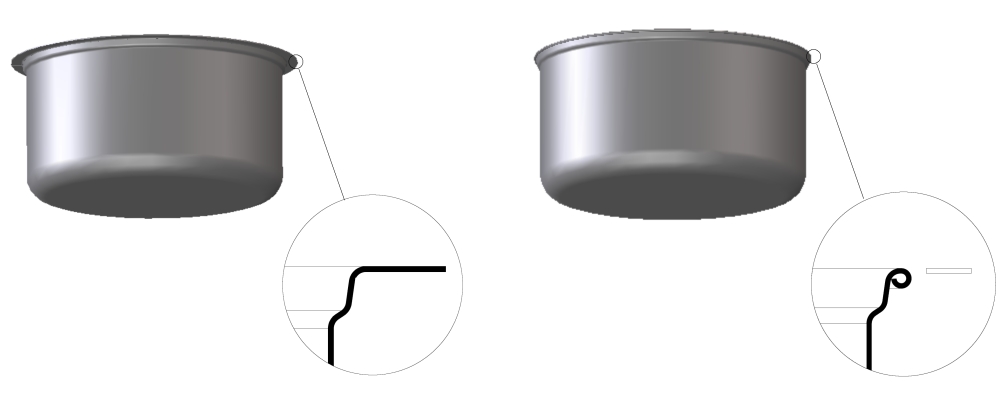

Production of round copper cauldrons.

CURLED SAMPLE

| Workpiece: | Deep drawn piece with flange |

| Material: | Copper |

| Performed operation: | Trimming / Pre-curling - Curling or Double Curling |

| Working cycle: | Semi-Automatic |

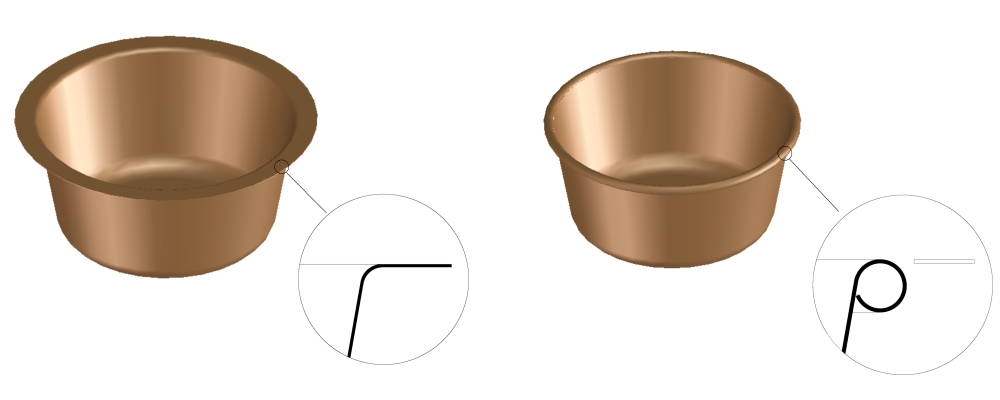

SAMPLE WITH REINFORCING ROD

EDGE WORKING - 1st Place Setting

| Workpiece: | Deep drawn piece with flange |

| Material: | Copper |

| Performed operation: | Trimming / Pre-Curling - Flange Bending |

| Working cycle: | Semi-Automatic |

ROD LOCKSEAMING - 2nd Place Setting

| Workpiece: | Deep drawn piece with bended flange and rod |

| Material: | Copper and normal Steel |

| Performed operation: | Rod Lockseaming |

| Working cycle: | Semi-Automatic |

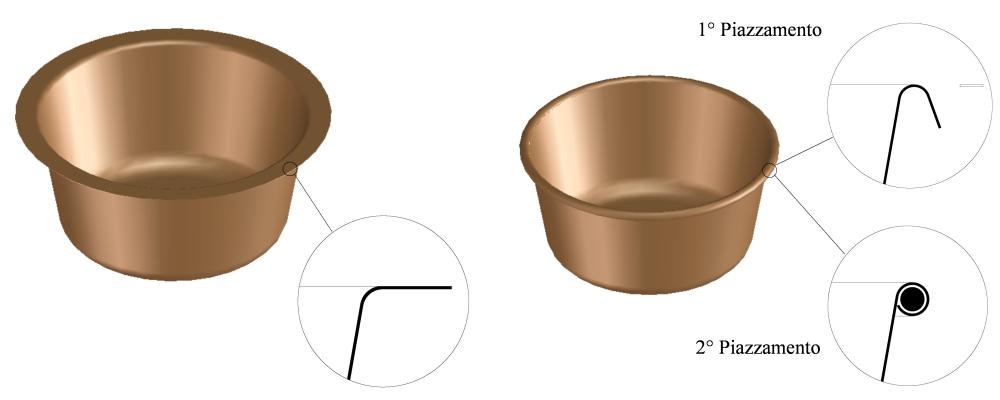

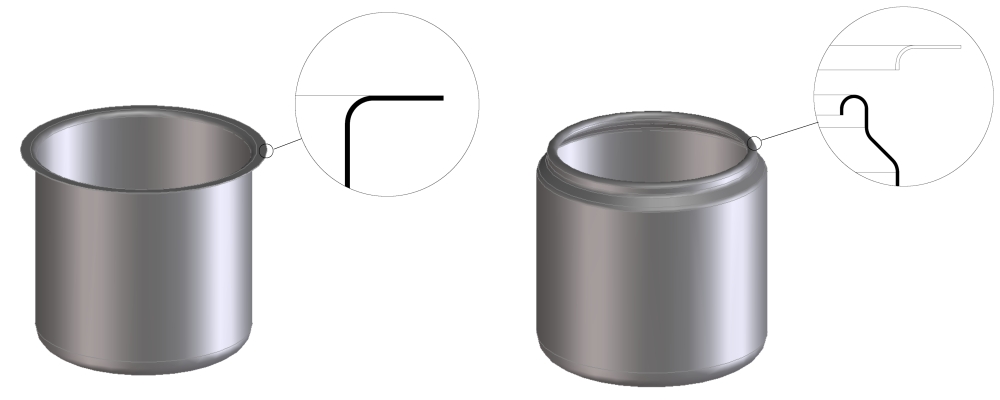

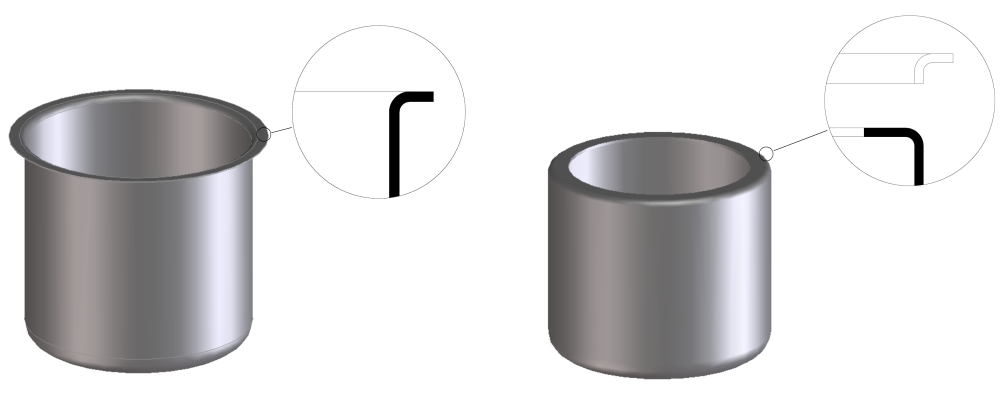

Production of round cooking pots.

| Workpiece: | Deep drawn piece with flange |

| Material: | Stainless Steel |

| Performed operation: | Trimming - Edge Chamfering - Curling |

| Working cycle: | Semi-Automatic or Automatic when included in a complete production line |

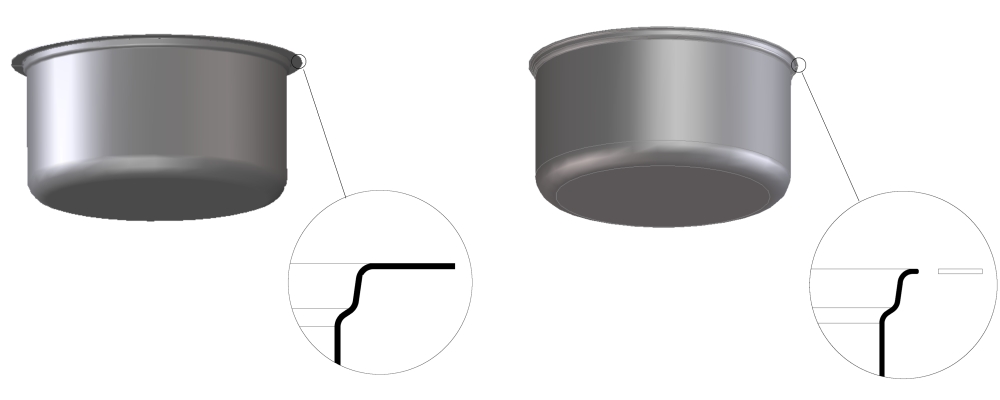

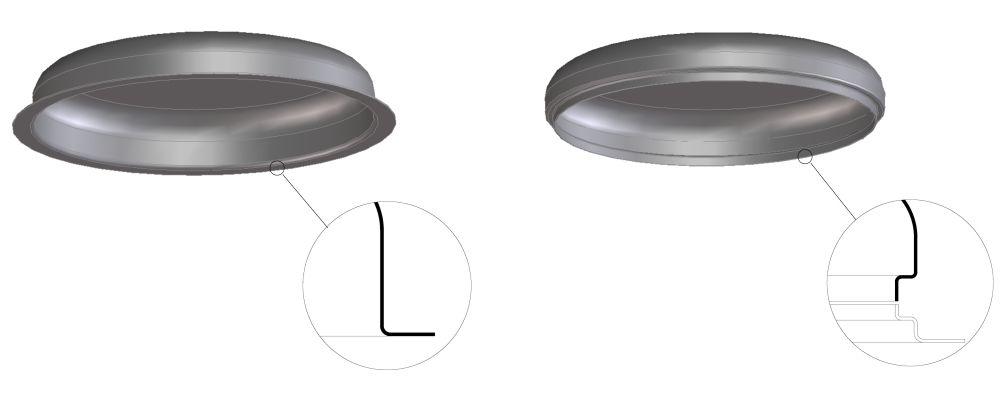

Production of round pot bottoms.

| Workpiece: | Deep drawn piece with flange or deep drawn piece with reduced flange to have less scrap |

| Material: | Stainless Steel |

| Performed operation: | Trimming - Edge Chamfering when necessary |

| Working cycle: | Semi-Automatic or Automatic when included in a complete production line |

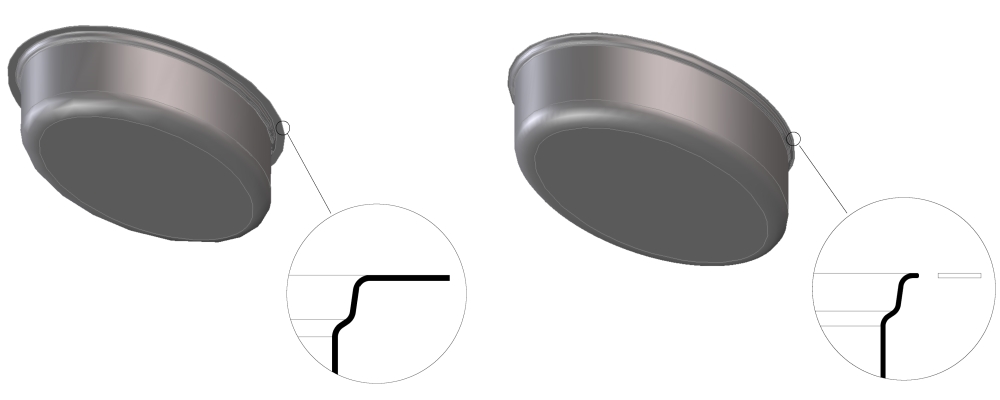

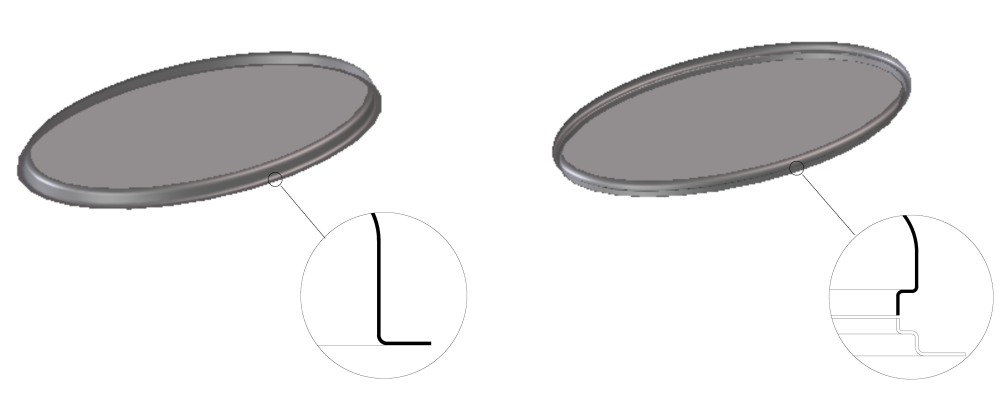

Production of oval cooking pots.

| Workpiece: | Deep drawn piece with flange |

| Material: | Stainless Steel |

| Performed operation: | Trimming - Curling |

| Working cycle: | Semi-Automatic |

Production of round pressure cookers.

BEADED SAMPLE

| Workpiece: | Deep drawn piece with flange |

| Material: | Stainless Steel |

| Performed operation: | Beading - Trimming - Deburring - Semi-Curling |

| Working cycle: | Semi-Automatic |

FLANGED SAMPLE

| Workpiece: | Deep drawn piece with reduced flange |

| Material: | Aluminim |

| Performed operation: | Trimming - Flanging |

| Working cycle: | Semi-Automatic or Automatic when included in a complete production line |

Production of round pot lids.

| Workpiece: | Deep drawn piece with flange or deep drawn piece with reduced flange to have less scrap |

| Material: | Stainless Steel |

| Performed operation: | Beading - Trimming - Edge Deburring when necessary |

| Working cycle: | Semi-Automatic or Automatic when included in a complete production line |

Production of oval pot lids.

| Workpiece: | Deep drawn piece with flange |

| Material: | Stainless Steel |

| Performed operation: | Beading - Trimming |

| Working cycle: | Semi-Automatic |

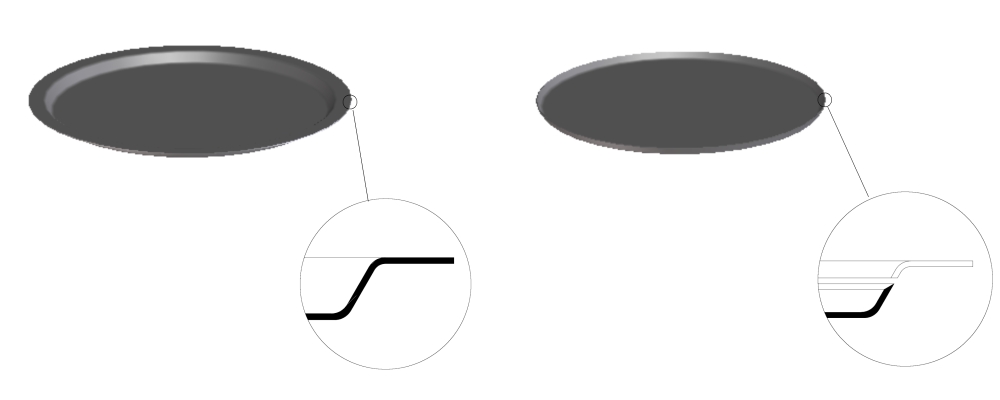

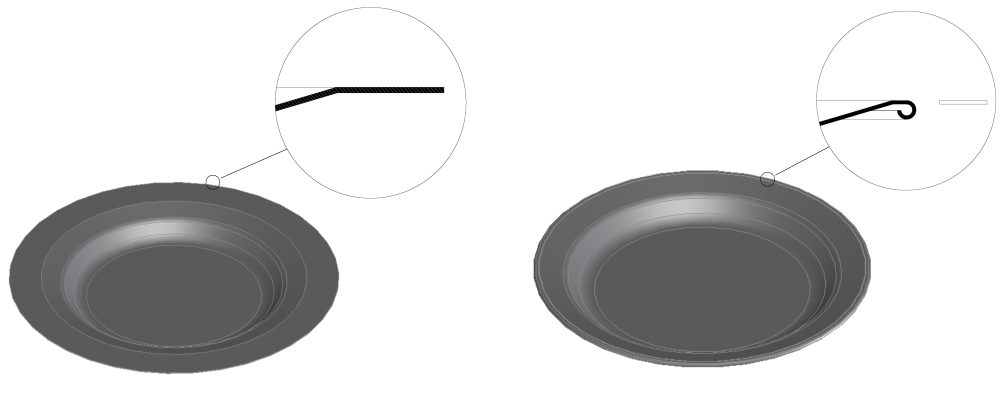

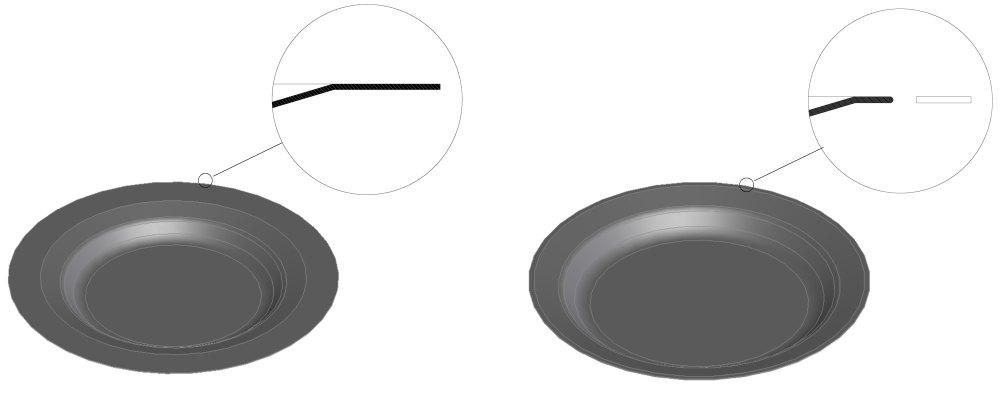

Production of dishes / round trays.

| Workpiece: | Deep drawn piece with flange |

| Material: | Stainless Steel - Brass - Silver |

| Performed operation: | Trimming - Edge Chamfering - Curling - Edge Shaping and Knurling when necessary |

| Working cycle: | Semi-Automatic |

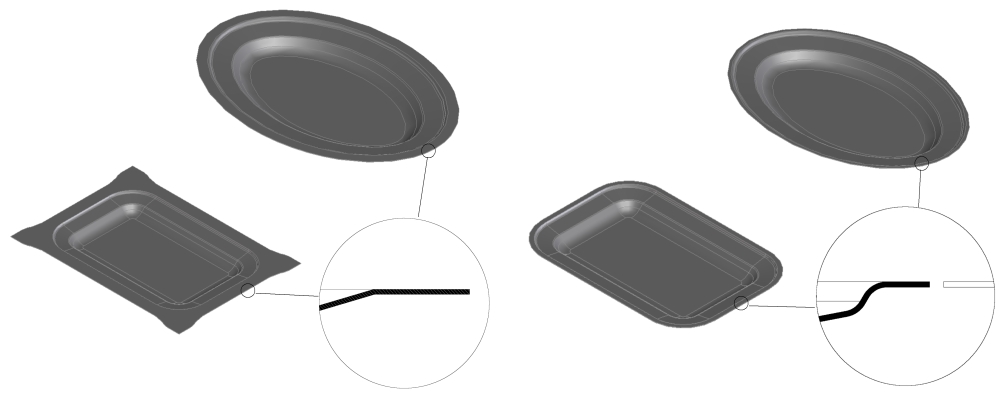

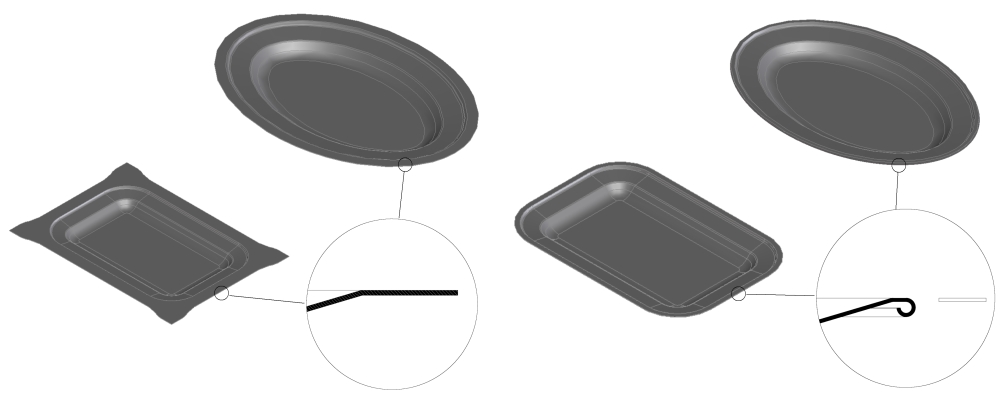

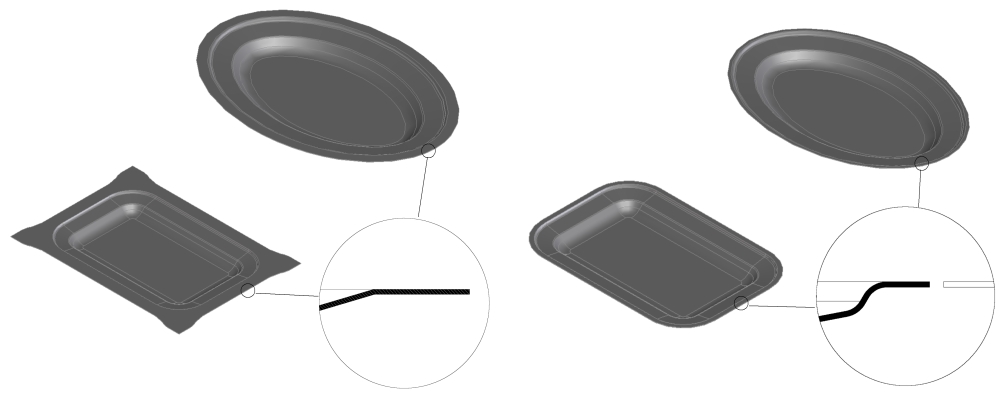

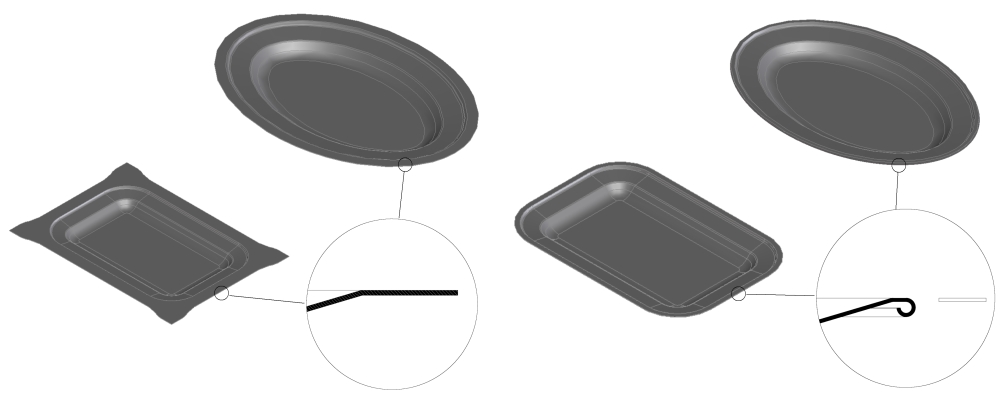

Production of oval trays.

| Workpiece: | Deep drawn piece with flange |

| Material: | Stainless Steel - Brass - Silver |

| Performed operation: | Rounding off - Trimming / Pre-Curling - Curling - Edge Shaping and Knurling when necessary |

| Working cycle: | Semi-Automatic |

Production of rectangular trays.

| Workpiece: | Deep drawn piece with flange |

| Material: | Stainless Steel - Brass - Silver |

| Performed operation: | Rounding off, when necessary - Trimming / Pre-Curling - Curling |

| Working Cycle: | Semi-Automatic |

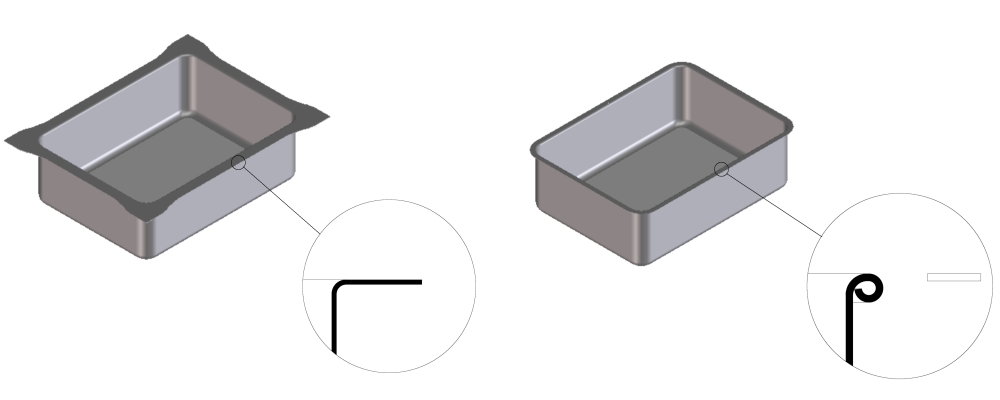

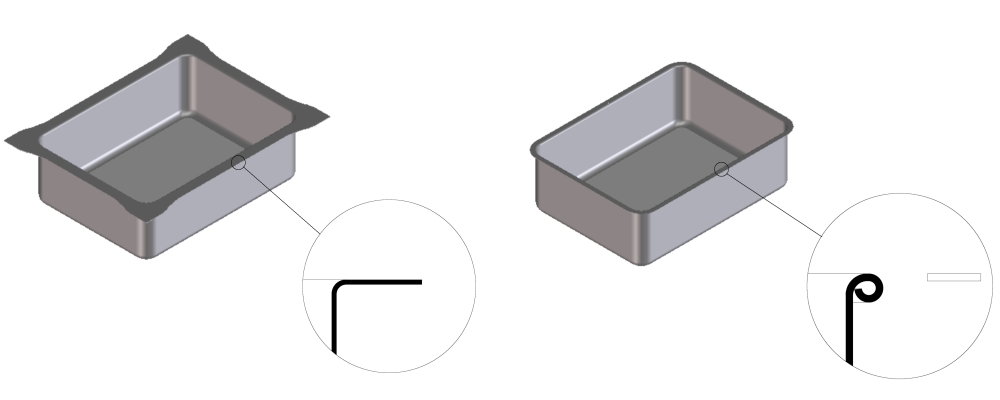

Production of rectangular cooking pots.

| Workpiece: | Deep drawn piece with flange |

| Material: | Normal Steel - Stainless Steel |

| Performed operation: | Rounding off, when necessary - Trimming / Pre-Curling - Curling |

| Working cycle: | Semi-Automatic |

Production of coffee pots.

| Workpiece: | Deep drawn piece with flange; alternatively, deep drawn piece with reduced flange to reduce the scrap |

| Material: | Stainless Steel |

| Performed operation: | Beading - Trimming - Edge Deburring when necessary |

| Working cycle: | Semi-Automatic or Automatic when included in a complete production line |

Production of kettles.

| Workpiece: | Deep drawn piece with blank flange; deep drawn bottom plate with flange or with blank flange when necessary |

| Material: | Stainless Steel or Aluminium |

| Performed operation: | Trimming / bottom plate Pre-Curling - Pre-Lockseaming - Lockseaming |

| Working cycle: | Semi-Automatic |