Production of half-shells for beer kegs.

| Workpiece: | Deep drawn piece with flange |

| Material: | Stainless Steel |

| Performed operation: | Trimming - Outer Ribbing |

| Working cycle: | Semi-Automatic or Automatic, when included in a complete production line |

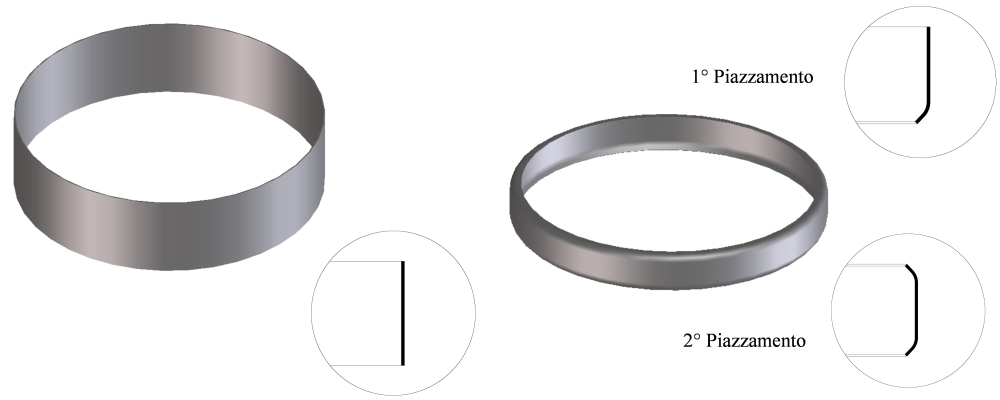

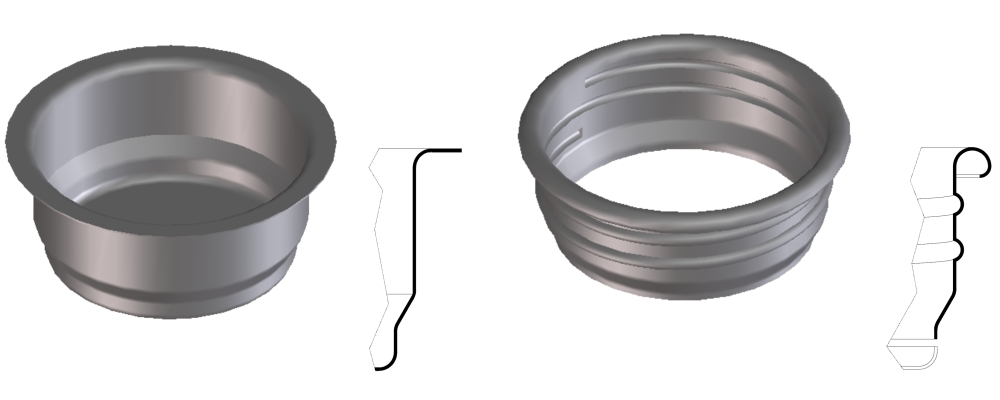

Production of footrings (simple and stackable) for beer kegs.

ROUND-STRAIGHT FOOTRING

| Workpiece: | Butt-welded rolled ring |

| Material: | Stainless Steel |

| Performed operation: | Bending / Edge Pre-Curling |

| Working cycle: | Semi-Automatic with two place settings to work in sequence both ends |

STOCKABLE FOOTRING

| Workpiece: | Shaped butt-welded rolled ring |

| Material: | Stainless Steel |

| Performed operation: | Bending / simultaneous Pre-Curling of both edges |

| Working cycle: | Semi-Automatic |

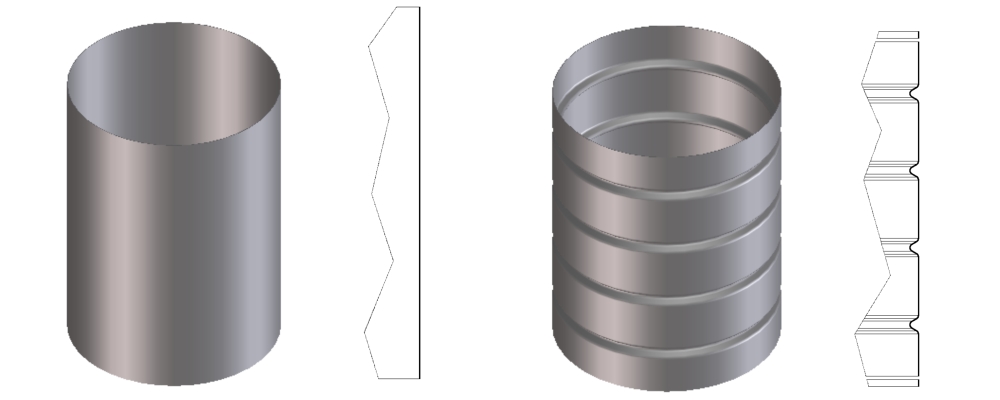

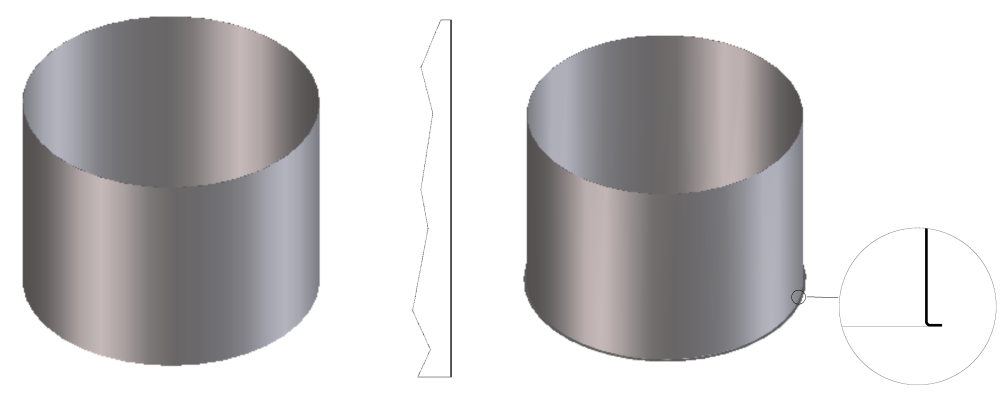

Production of bodies for nuclear waste containers.

| Workpiece: | Roll-bended and butt-welded body |

| Material: | Stainless Steel |

| Performed operation: | Trimming - no. 2 Ribbings |

| Working cycle: | Semi-automatic with two place settings to work in sequence both ends |

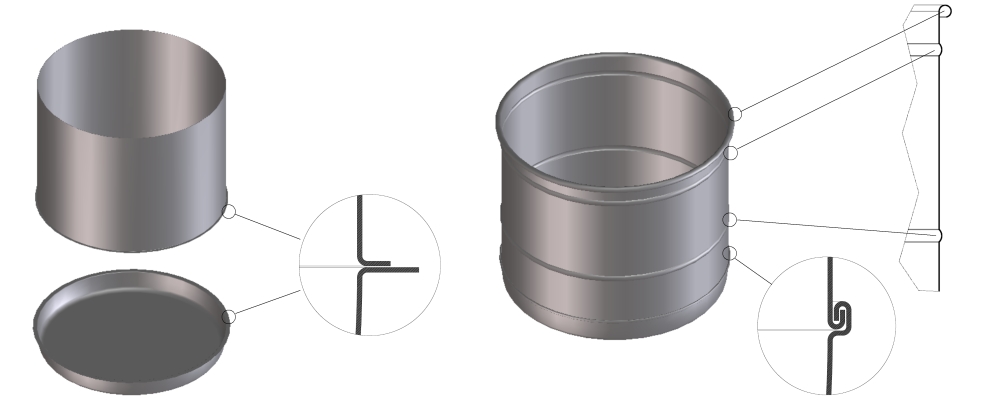

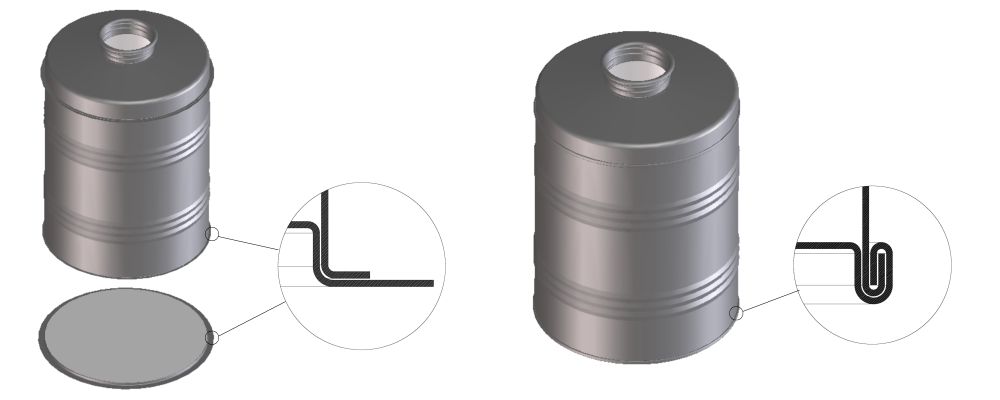

Production of cylindrical buckets for liquids, consisting of shaped body and bottom end, lockseamed together.

BODY WORKING PROCESS

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers |

| Material: | Galvanized normal steel |

| Performed operation: | Lower edge outward Flanging |

| Working cycle: | Semi-Automatic |

BODY LOCKSEAMING ONTO THE BOTTOM END

| Workpiece: | Shaped outward flanged body with overlapping edges welded with pressure rollers; deep drawn bottom end with blank flange |

| Material: | Galvanized normal steel |

| Performed operation: | Intermediate Ribbings- Pre-Lockseaming - 4-layer Lockseaming - edge Curling |

| Working cycle: | Semi-Automatic |

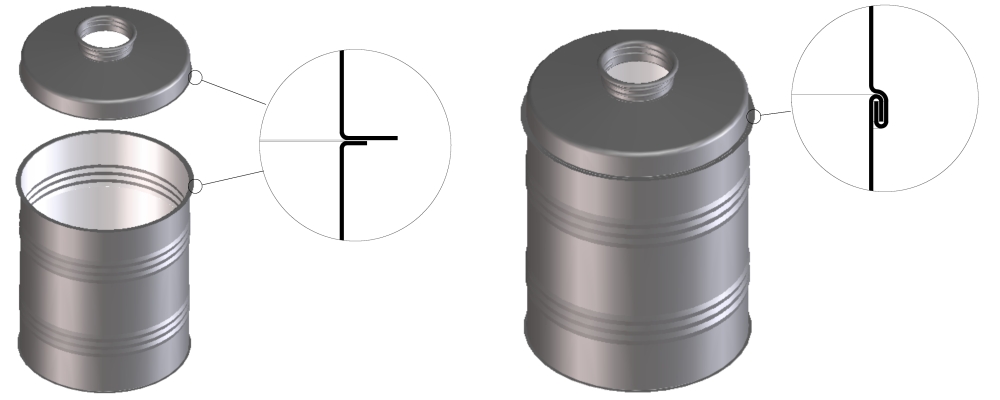

Production of various components for oil containers, consisting of shaped body, bottom end and cover, lockseamed together, as well as end cap.

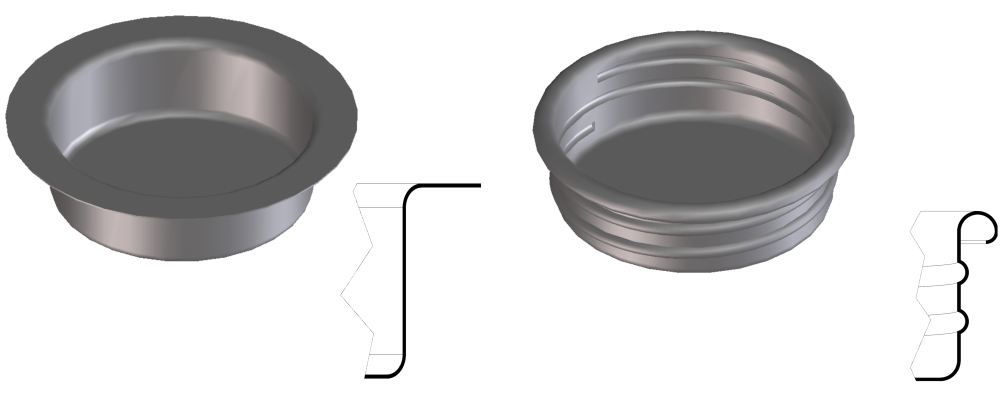

TOP CAP WORKING

| Workpiece: | Deep drawn piece with pre-curled blank flange |

| Material: | Stainless Steel |

| Performed operation: | Male piece Threading |

| Working cycle: | Semi-Automatic |

NECK WORKING

| Workpiece: | Deep drawn piece with pre-curled blank flange |

| Material: | Stainless Steel |

| Performed operation: | Edge Semi-Curling - female piece Threading - upper cover Trimming |

| Working cycle: | Semi-Automatic |

BODY LOCKSEAMING ONTO THE COVER

| Workpiece: | Shaped and outward flanged body with butt-welded edges; deep drawn cover with pre-curled blank flange and opening |

| Material: | Stainless Steel |

| Performed operation: | Pre-Lockseaming - 4-layer Lockseaming |

| Working cycle: | Semi-Automatic |

BODY LOCKSEAMING ONTO THE BOTTOM END

| Workpiece: | Outward flanged body with cover and opening on deep drawn bottom end with pre-curled blank flange |

| Material: | Stainless Steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic |

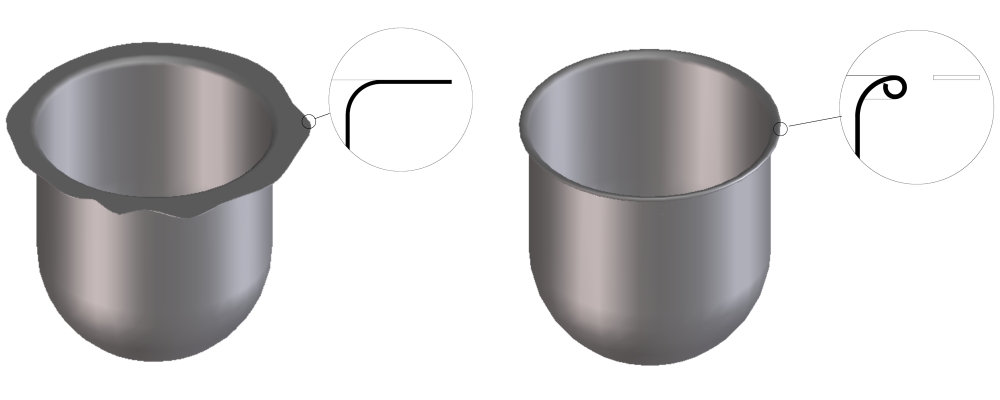

Production of mixing bowls for kneading machines.

| Workpiece: | Deep drawn piece with flange |

| Material: | Stainless Steel |

| Performed operation: | Trimming - Chamfering - Curling |

| Working cycle: | Semi-Automatic |

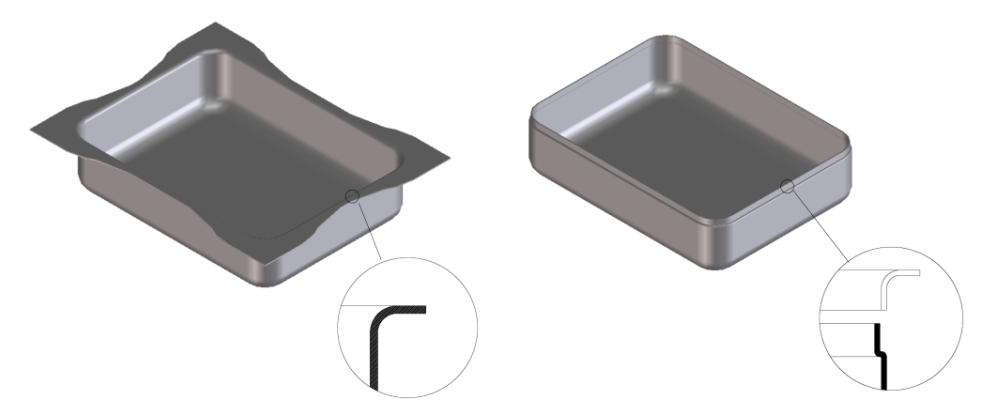

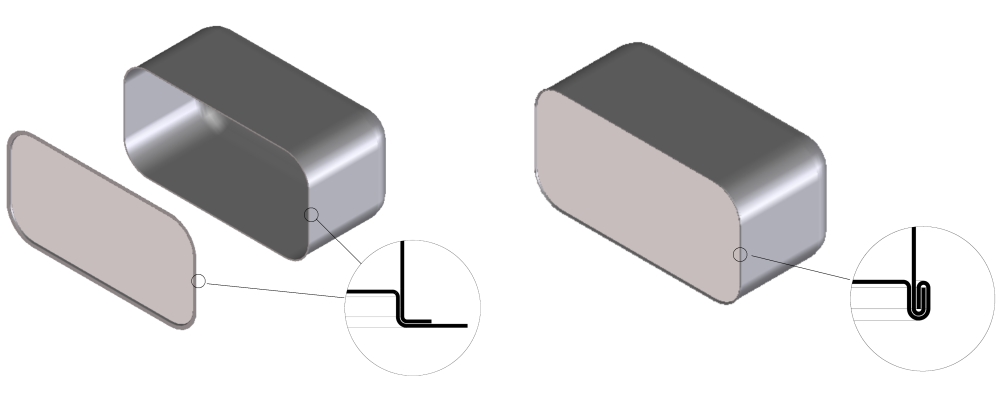

Production of rectangular boxes for various materials, consisting of container and lid.

LID

| Workpiece: | Deep drawn piece with flange |

| Material: | Normal Steel or Stainless Steel |

| Performed operation: | Edge Trimming - Braking of scrap into two parts in case workpiece is deep drawn with no flange (when necessary) |

| Working cycle: | Semi-Automatic |

BOX

| Workpiece: | Deep drawn piece with flange |

| Material: | Normal Steel or Stainless Steel |

| Performed operation: | Trimming - Beading |

| Working cycle: | Semi-Automatic |

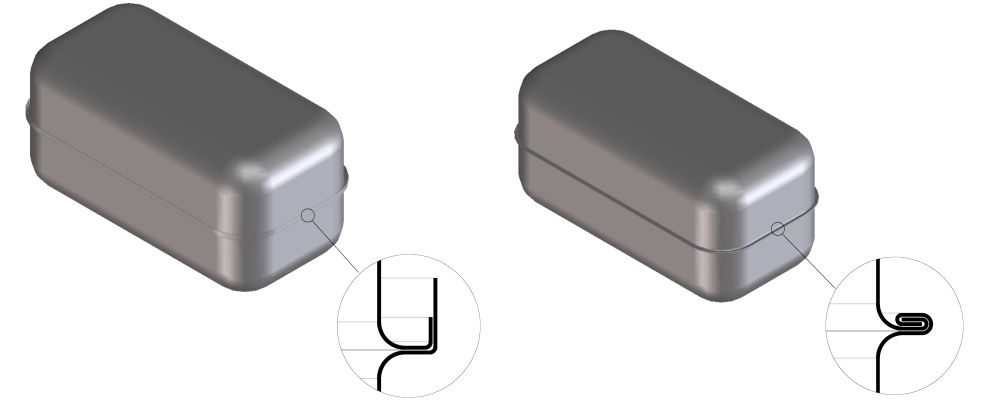

Production of rectangular tanks with intermediate joint for various liquids, consisting of male and female half-shells.

| Workpiece: | Deep drawn male and female pieces with shaped blank edge |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming (sealant coating when necessary) |

| Working cycle: | Semi-Automatic |

Production of rectangular tanks with joint on the base for various liquids, consisting of body and bottom end.

| Workpiece: | Body: deep drawn piece with blank flange; Bottom end: deep drawn piece with pre-curled blank flange |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic |

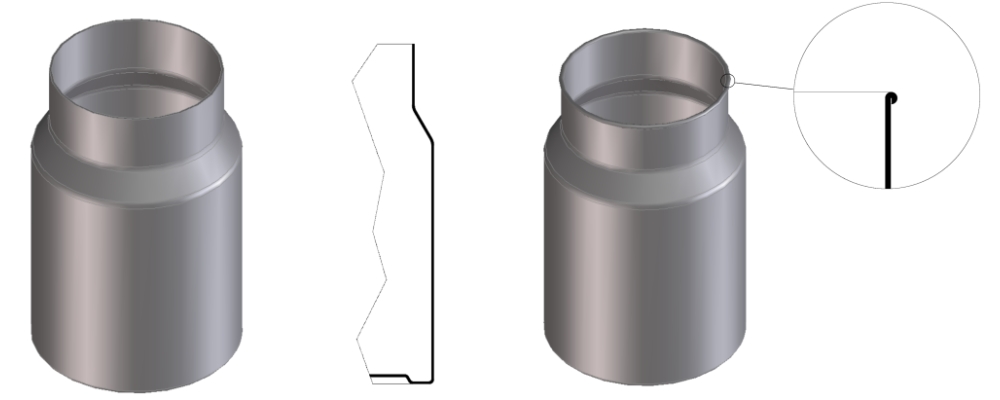

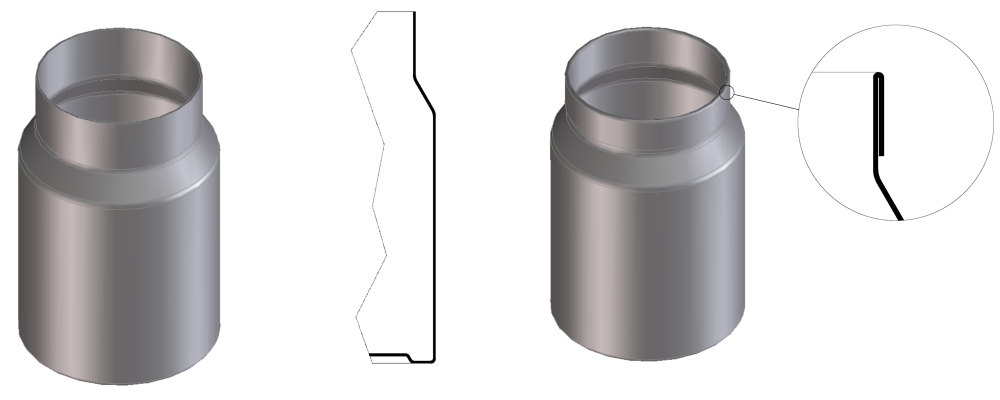

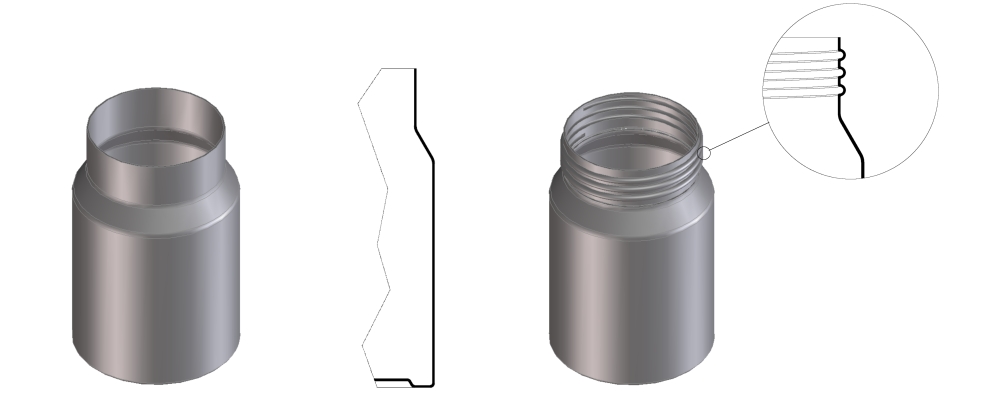

Production of tanks for spray gun bottles with various neck workings.

CURLED NECK

| Workpiece: | Deep drawn piece with narrowed trimmed neck |

| Material: | Aluminium |

| Performed operation: | Edge Deburring - outward Curling |

| Working cycle: | Semi-Automatic |

DOUBLE CURLED NECK

| Workpiece: | Deep drawn piece with narrowed trimmed neck |

| Material: | Aluminium |

| Performed operation: | Edge Deburring - outward Curling - curl Flattening |

| Working cycle: | Semi-Automatic |

THREADED NECK

| Workpiece: | Deep drawn piece with narrowed trimmed neck |

| Material: | Aluminium |

| Performed operation: | Threading |

| Working cycle: | Semi-Automatic |

РЕШЕНИЯ

Oil&Gas

Газовые баллоны, цилиндрические и тороидальные резервуары. Наши решения позволяют изготавливать баллоны разных размеров в рамках одной и той же системы, оптимизируя время настройки и управление системой, что, в свою очередь, дает преимущества в производительности и продолжительности цикла.

Вентиляция

Измеримые преимущества в технологии пресс-форм и в используемой автоматизации, которые позволяют сократить количество этапов процесса и уменьшить количество брака с последующим снижением затрат, а также сокращением площадей задействованных промышленных цехов. Наша автоматическая линия под ключ может производить вентиляционные каналы, такие как фитинги, отводы, переходы и Т-образные ответвительные муфты.

Товары для дома

Мы предлагаем производственные решения для разработки кастрюль, крышек, сковородок и противней, которые позволяют оптимизировать процесс вытяжки, регулируя скорость, силы, прижим заготовок и экстракторы. Операции, которые имеют особое значение, когда используются такие материалы, как нержавеющая или многослойная сталь, и когда вы хотите получить высокое качество детали, изготовленной без дефектов.

Электробытовые приборы

Мы проектируем и разрабатываем линии под ключ для моек, вытяжек из нержавеющей стали, деталей для духовок и варочных панелей, с возможностью предоставления автоматических систем для смены стола и блокировки формы, интерфейса линии и готовности к дистанционному обслуживанию.

Нагрев&охлаждение

Мы присутствуем во всем мире с производственными линиями под ключ для производства расширительных баков, водонагревателей, тепловых насосов и дверей для холодильников. Мы предлагаем производственные решения с высокой степенью гибкости и с возможностью подключения к заводской системе.

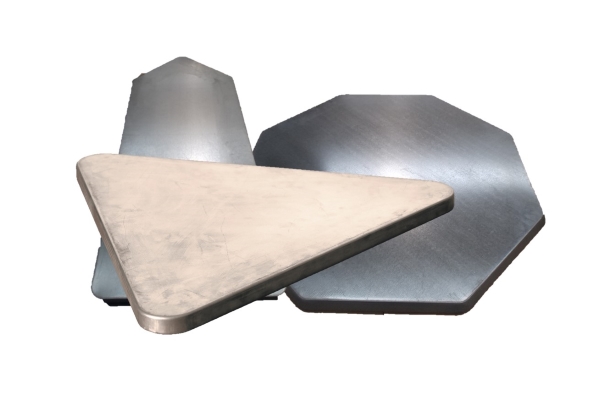

Дорожные знаки

Мы присутствуем на рынке с инновационным производством многоугольных дорожных знаков. Начиная с предварительно нарезанного листового металла, благодаря нашим кромкооблицовочным станкам CNC, мировому лидеру, мы предлагаем возможность изготовления дорожных знаков любой формы из стали и алюминия.