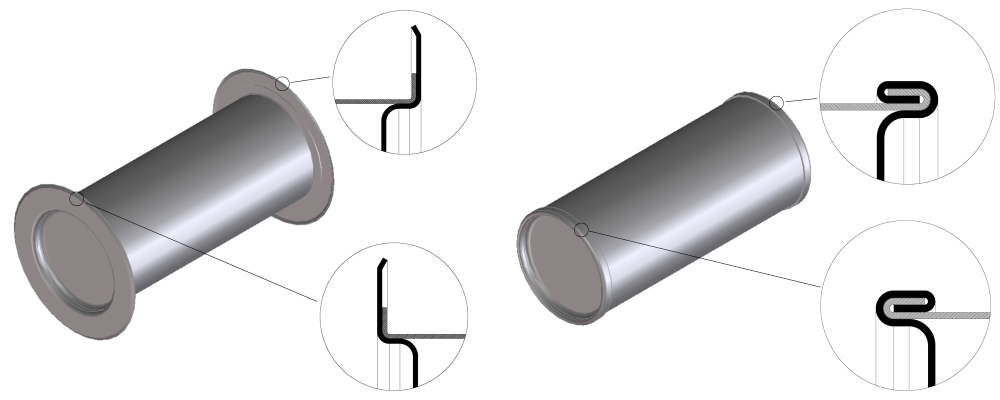

Preparation and assembly by caulking of supports for shock absorbers, consisting of bushing and flange.

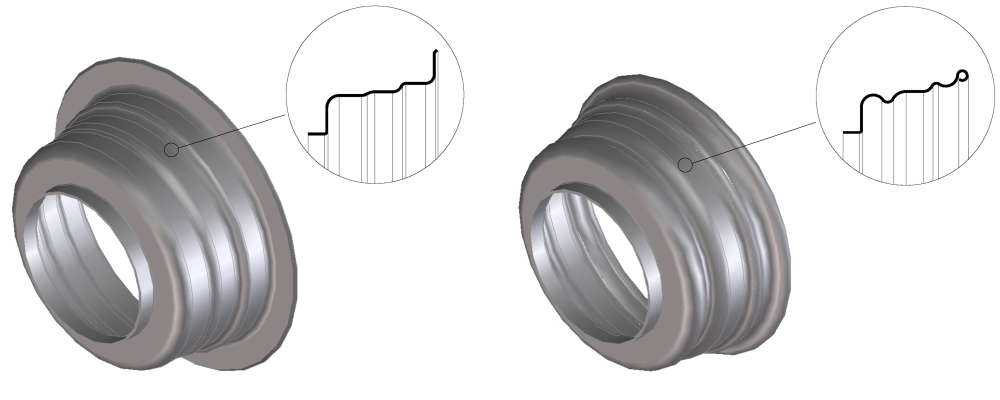

BUSH WORKING

| Workpiece: | Shaped deep drawn piece with blank flange |

| Material: | Normal steel |

| Performed operation: | Ribbing - Edge Curling |

| Working cycle: | Semi-Automatic |

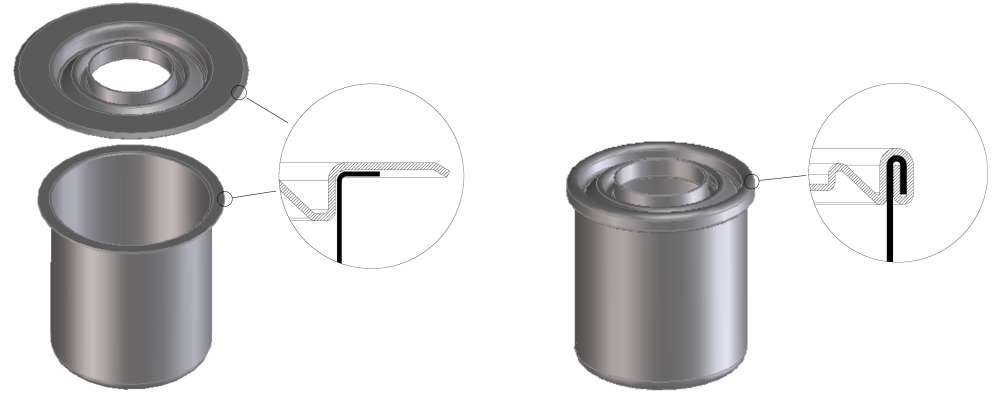

ASSEMBLING PROCESS

| Workpiece: | Shaped deep drawn bush - shaped deep drawn flange |

| Material: | Normal steel |

| Performed operation: | Calking |

| Working cycle: | Semi-Automatic |

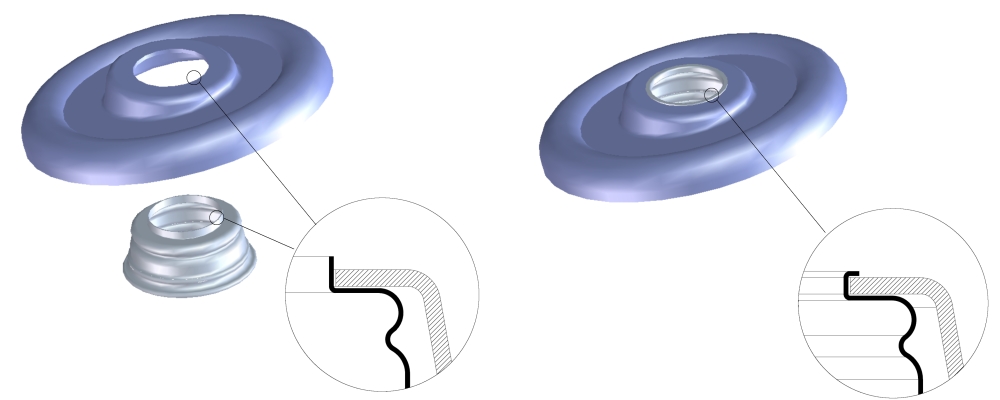

Assembly by caulking of protective elements for car joints, consisting of metal bushing and rubber casing.

| Workpiece: | Shaped deep drawn bush - shaped rubber casing |

| Material: | Normal steel - Rubber |

| Performed operation: | Calking of the two elements |

| Working cycle: | Semi-Automatic |

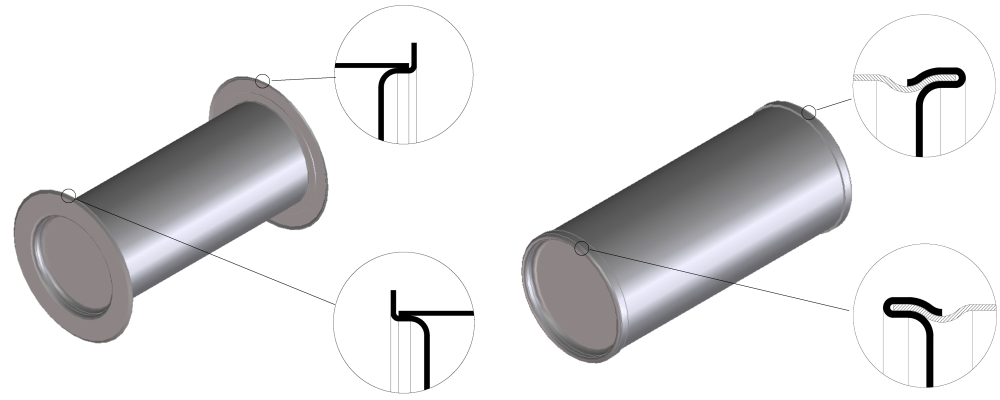

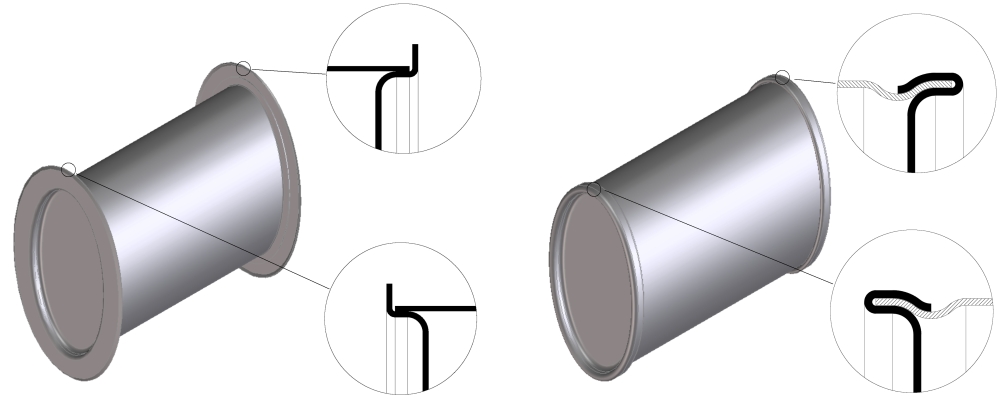

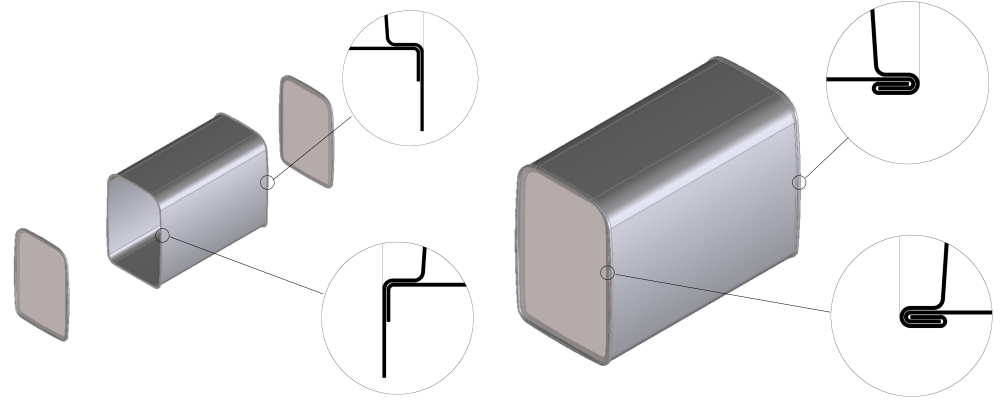

Assembly by 3- or 5-layer lockseaming of car silencers, consisting of body, two bottom ends and internal components.

5-LAYER LOCKSEAMING

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers and flanged ends; deep drawn bottom ends with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic, with two place settings to work in sequence both ends |

3-LAYER LOCKSEAMING

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers; deep drawn bottom ends with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | 3-layer Lockseaming |

| Working cycle: | Semi-Automatic, with two place settings to work in sequence both ends |

ONE PLACE SETTING SOLUTION

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers and/or flanged ends; deep drawn bottom ends with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming and/or simultaneous 3- or 5-layer Lockseaming of the ends |

| Working cycle: | Semi-Automatic, with one place setting, subject to the use of a two-head beading machine |

Assembly by 5-layer lockseaming of car silencers, consisting of body, two bottom ends and internal components.

| Workpiece: | Shaped tubular body with overlapping edges welded with pressure rollers; deep drawn bottom ends with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic, with two place settings to work in sequence both ends |

ONE PLACE SETTING SOLUTION

| Workpiece: | Shaped tubular body with overlapping edges welded with pressure rollers and flanged ends; deep drawn bottom ends with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - simultaneous 5-layer Lockseaming of the ends |

| Working cycle: | Semi-Automatic, with one place setting, subject to the use of a two-head beading machine |

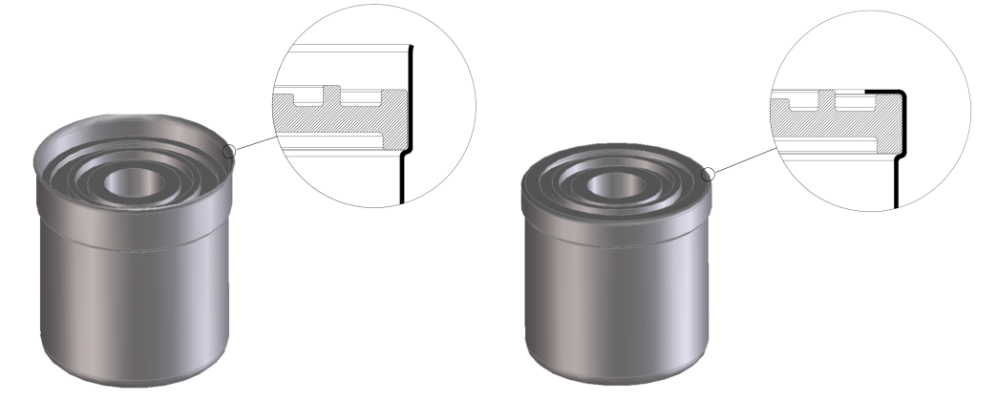

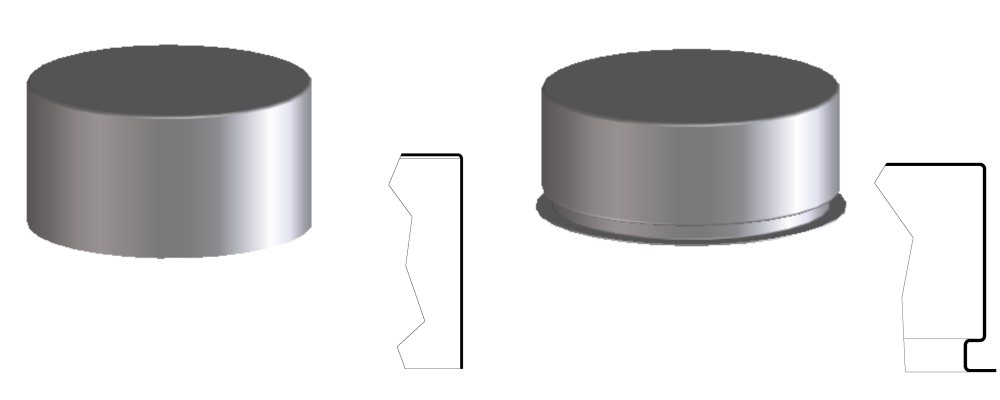

Assembly by caulking of oil filters for cars, consisting of deep drawn piece, aluminum bottom end and internal components.

| Workpiece: | Deep drawn piece with reducted flange; aluminium bottom end; inside components |

| Material: | Normal steel - Aluminium |

| Performed operation: | Caulking of the deep drawn edge onto the aluminium bottom end |

| Working cycle: | Semi-Automatic or Automatic, when included in a complete production line |

Assembly by 5-layer lockseaming of oil filters for cars, consisting of deep drawn piece, bottom end and internal components.

| Workpiece: | Deep drawn piece with blank flange; deep drawn bottom end with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic or Automatic, when included in a complete production line |

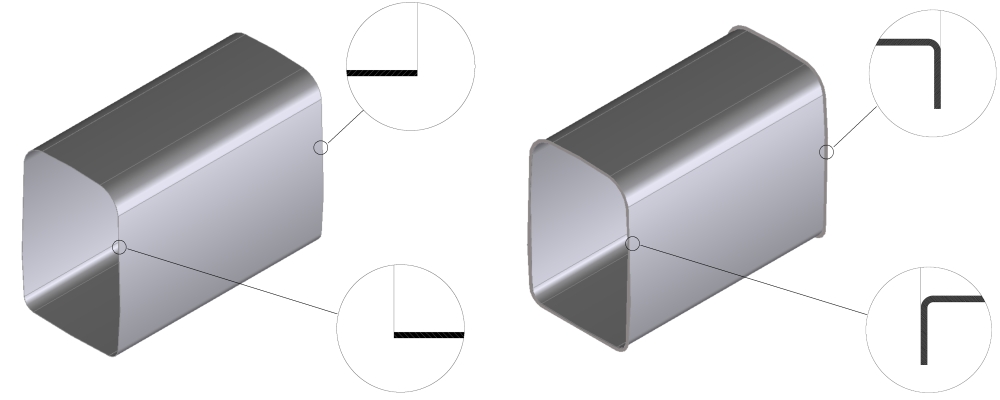

Preparation and assembly by 5-layer lockseaming of rectangular fuel tanks, consisting of body, two bottom ends and internal components.

BODY WORKING PROCESS

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers |

| Material: | Normal steel |

| Perfomed operation: | Outward Flanging |

| Working cycle: | Semi-Automatic, with two place settings to work in sequence both ends |

ASSEMBLING PROCESS

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers and with outward flanged edges |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic, with two place settings to work in sequence both ends |

ONE PLACE SETTING SOLUTION

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers and with outward flanged edges |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - simultaneous 5-layer Lockseaming on both edges |

| Working cycle: | Semi-Automatic with one place setting, subject to the use of a two-head beading machine |

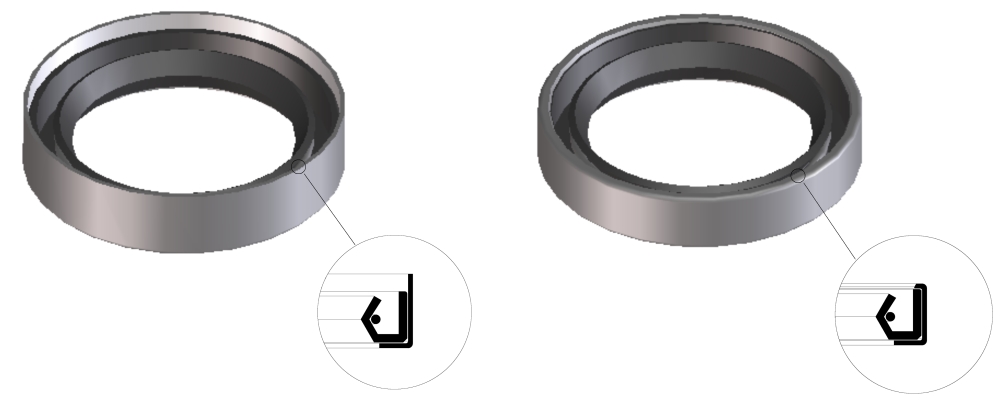

Assembly and finishing of sealing rings for rotating shafts, consisting of metal ring and seal.

| Workpiece: | Shaped deep drawn ring - Seal |

| Material: | Normal steel - Rubber |

| Performed operation: | Edge Chamfering - Calking of the two components - outer diameter Turning |

| Working cycle: | Semi-Automatic |

Production of casings for pressure gauges.

| Workpiece: | Deep drawn piece with reduced flange |

| Material: | Stainless Steel |

| Performed operation: | Trimming - Ribbing - edge outward Flanging |

| Working cycle: | Semi-Automatic |

РЕШЕНИЯ

Oil&Gas

Газовые баллоны, цилиндрические и тороидальные резервуары. Наши решения позволяют изготавливать баллоны разных размеров в рамках одной и той же системы, оптимизируя время настройки и управление системой, что, в свою очередь, дает преимущества в производительности и продолжительности цикла.

Вентиляция

Измеримые преимущества в технологии пресс-форм и в используемой автоматизации, которые позволяют сократить количество этапов процесса и уменьшить количество брака с последующим снижением затрат, а также сокращением площадей задействованных промышленных цехов. Наша автоматическая линия под ключ может производить вентиляционные каналы, такие как фитинги, отводы, переходы и Т-образные ответвительные муфты.

Товары для дома

Мы предлагаем производственные решения для разработки кастрюль, крышек, сковородок и противней, которые позволяют оптимизировать процесс вытяжки, регулируя скорость, силы, прижим заготовок и экстракторы. Операции, которые имеют особое значение, когда используются такие материалы, как нержавеющая или многослойная сталь, и когда вы хотите получить высокое качество детали, изготовленной без дефектов.

Электробытовые приборы

Мы проектируем и разрабатываем линии под ключ для моек, вытяжек из нержавеющей стали, деталей для духовок и варочных панелей, с возможностью предоставления автоматических систем для смены стола и блокировки формы, интерфейса линии и готовности к дистанционному обслуживанию.

Нагрев&охлаждение

Мы присутствуем во всем мире с производственными линиями под ключ для производства расширительных баков, водонагревателей, тепловых насосов и дверей для холодильников. Мы предлагаем производственные решения с высокой степенью гибкости и с возможностью подключения к заводской системе.

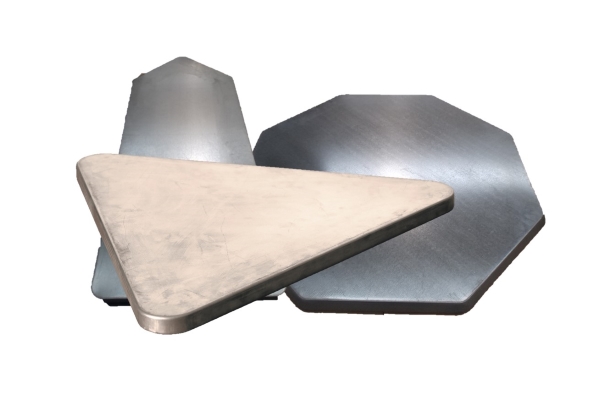

Дорожные знаки

Мы присутствуем на рынке с инновационным производством многоугольных дорожных знаков. Начиная с предварительно нарезанного листового металла, благодаря нашим кромкооблицовочным станкам CNC, мировому лидеру, мы предлагаем возможность изготовления дорожных знаков любой формы из стали и алюминия.