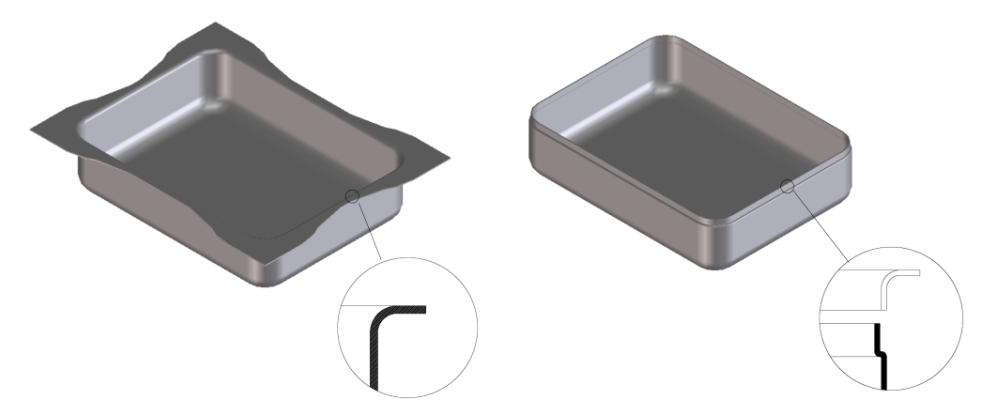

Production of half-shells for beer kegs.

| Workpiece: | Deep drawn piece with flange |

| Material: | Stainless Steel |

| Performed operation: | Trimming - Outer Ribbing |

| Working cycle: | Semi-Automatic or Automatic, when included in a complete production line |

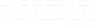

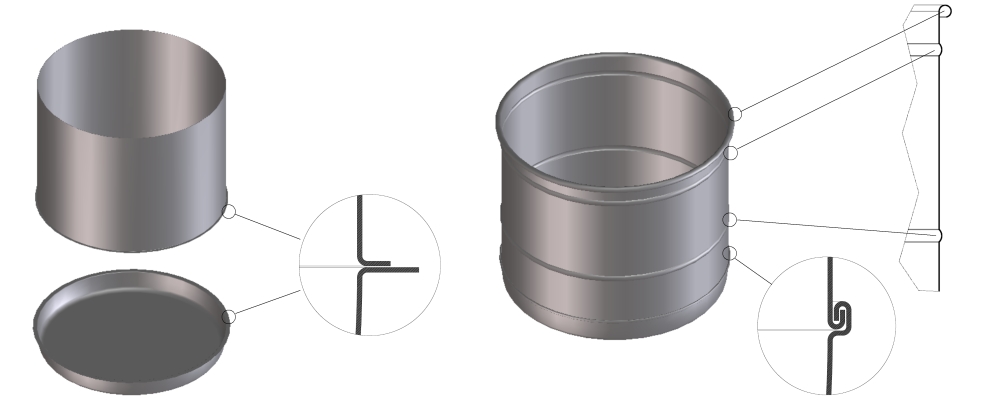

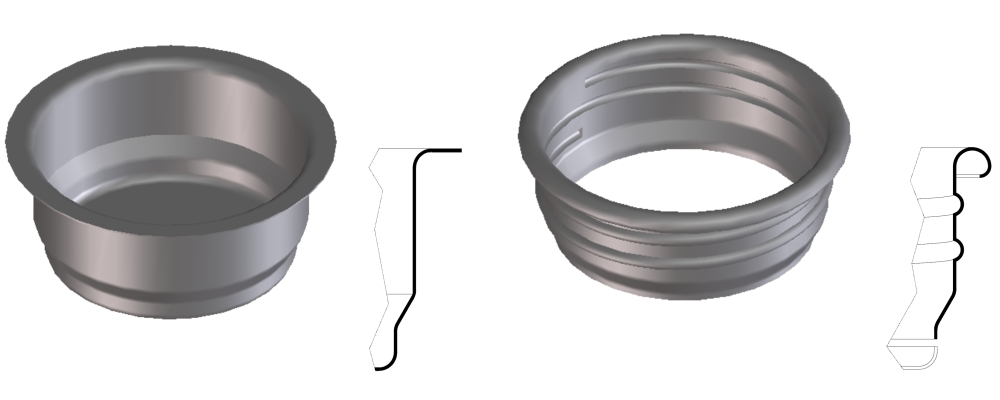

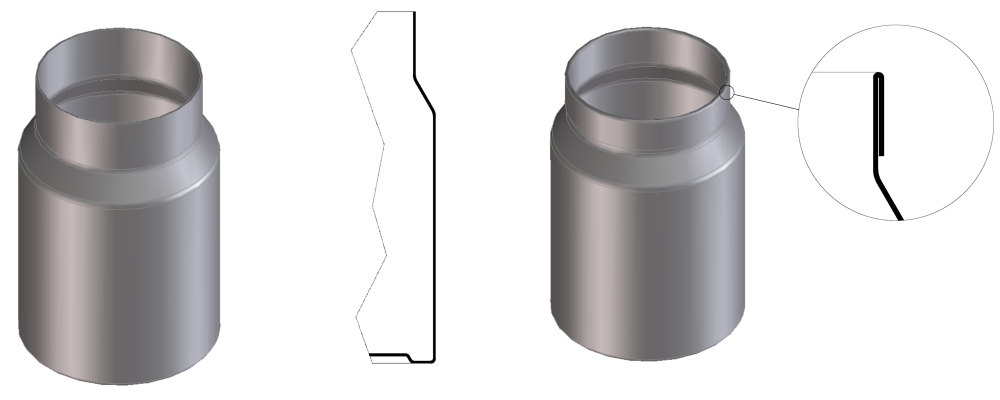

Production of footrings (simple and stackable) for beer kegs.

ROUND-STRAIGHT FOOTRING

| Workpiece: | Butt-welded rolled ring |

| Material: | Stainless Steel |

| Performed operation: | Bending / Edge Pre-Curling |

| Working cycle: | Semi-Automatic with two place settings to work in sequence both ends |

STOCKABLE FOOTRING

| Workpiece: | Shaped butt-welded rolled ring |

| Material: | Stainless Steel |

| Performed operation: | Bending / simultaneous Pre-Curling of both edges |

| Working cycle: | Semi-Automatic |

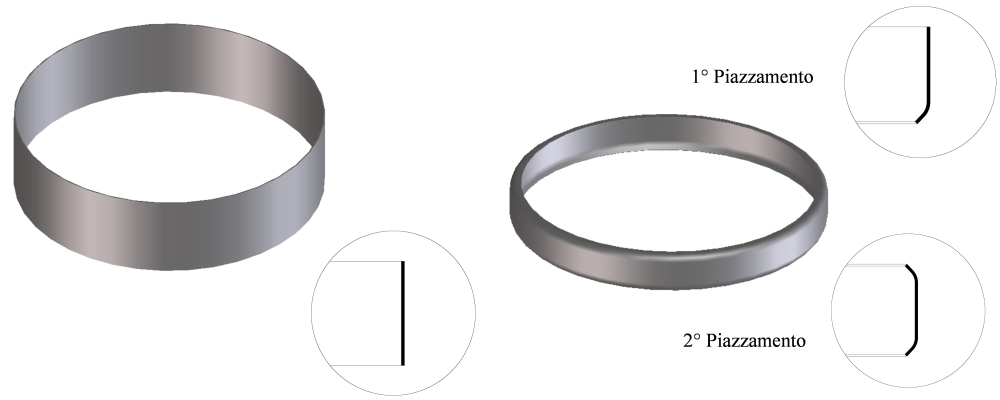

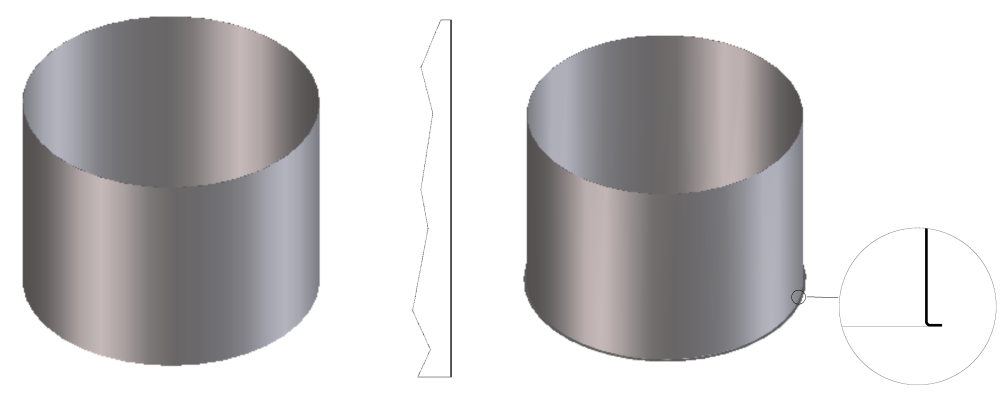

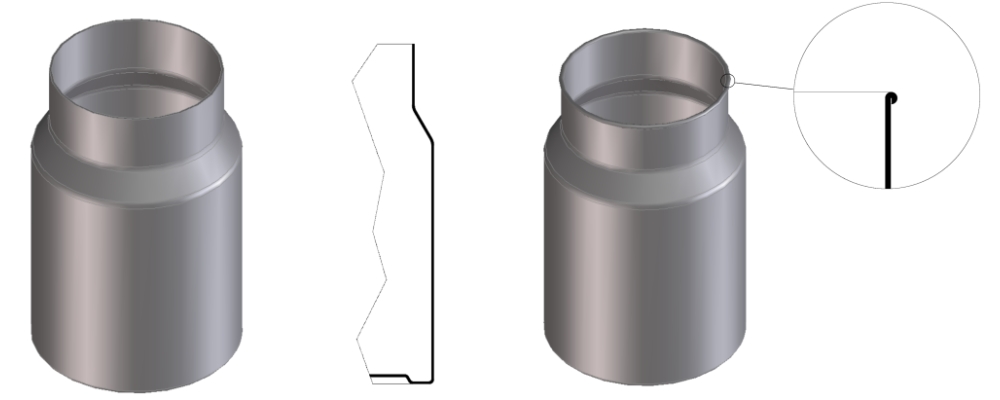

Production of bodies for nuclear waste containers.

| Workpiece: | Roll-bended and butt-welded body |

| Material: | Stainless Steel |

| Performed operation: | Trimming - no. 2 Ribbings |

| Working cycle: | Semi-automatic with two place settings to work in sequence both ends |

Production of cylindrical buckets for liquids, consisting of shaped body and bottom end, lockseamed together.

BODY WORKING PROCESS

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers |

| Material: | Galvanized normal steel |

| Performed operation: | Lower edge outward Flanging |

| Working cycle: | Semi-Automatic |

BODY LOCKSEAMING ONTO THE BOTTOM END

| Workpiece: | Shaped outward flanged body with overlapping edges welded with pressure rollers; deep drawn bottom end with blank flange |

| Material: | Galvanized normal steel |

| Performed operation: | Intermediate Ribbings- Pre-Lockseaming - 4-layer Lockseaming - edge Curling |

| Working cycle: | Semi-Automatic |

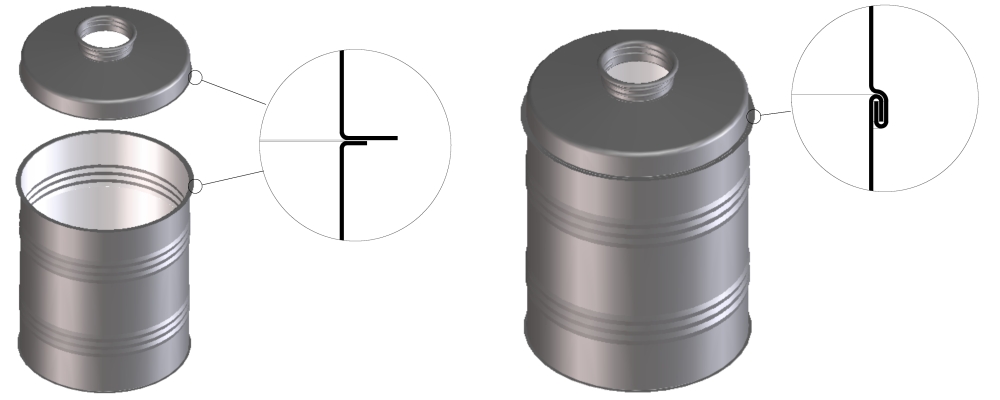

Production of various components for oil containers, consisting of shaped body, bottom end and cover, lockseamed together, as well as end cap.

TOP CAP WORKING

| Workpiece: | Deep drawn piece with pre-curled blank flange |

| Material: | Stainless Steel |

| Performed operation: | Male piece Threading |

| Working cycle: | Semi-Automatic |

NECK WORKING

| Workpiece: | Deep drawn piece with pre-curled blank flange |

| Material: | Stainless Steel |

| Performed operation: | Edge Semi-Curling - female piece Threading - upper cover Trimming |

| Working cycle: | Semi-Automatic |

BODY LOCKSEAMING ONTO THE COVER

| Workpiece: | Shaped and outward flanged body with butt-welded edges; deep drawn cover with pre-curled blank flange and opening |

| Material: | Stainless Steel |

| Performed operation: | Pre-Lockseaming - 4-layer Lockseaming |

| Working cycle: | Semi-Automatic |

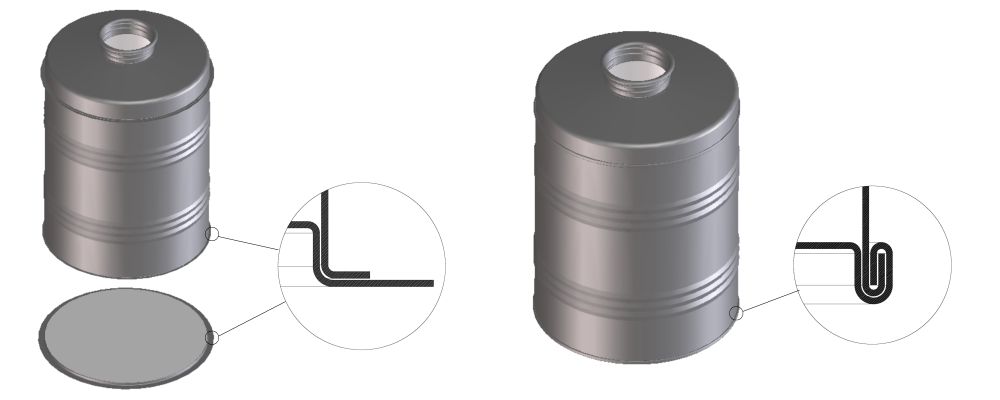

BODY LOCKSEAMING ONTO THE BOTTOM END

| Workpiece: | Outward flanged body with cover and opening on deep drawn bottom end with pre-curled blank flange |

| Material: | Stainless Steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic |

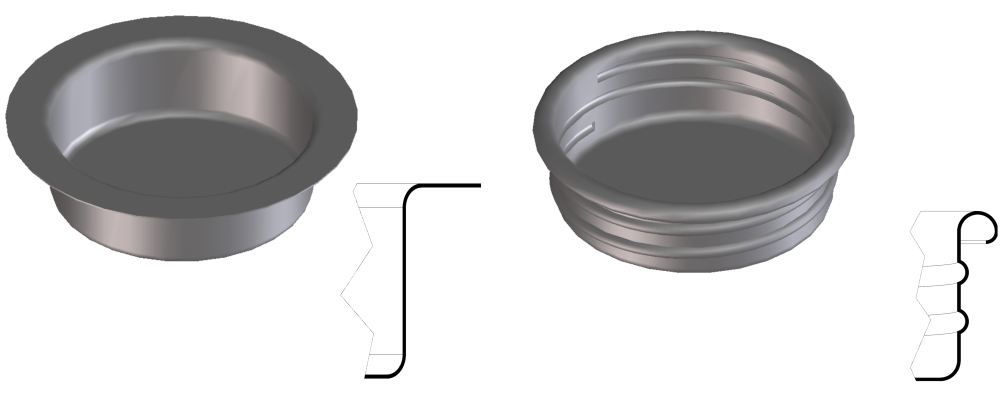

Production of mixing bowls for kneading machines.

| Workpiece: | Deep drawn piece with flange |

| Material: | Stainless Steel |

| Performed operation: | Trimming - Chamfering - Curling |

| Working cycle: | Semi-Automatic |

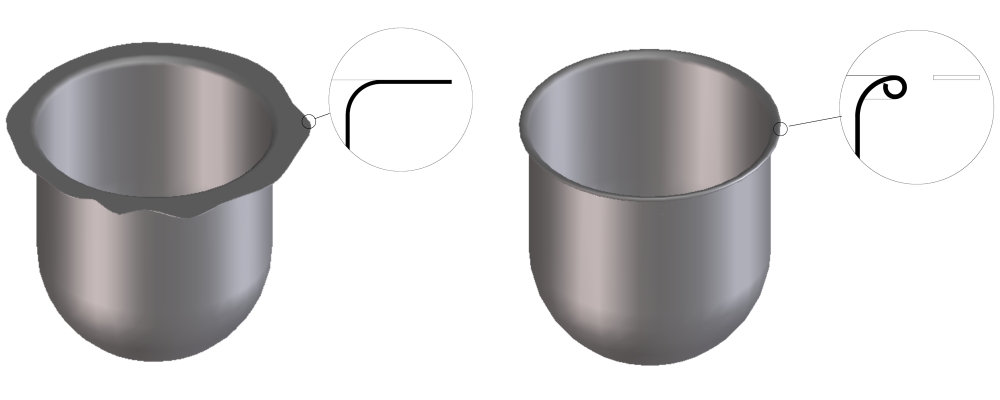

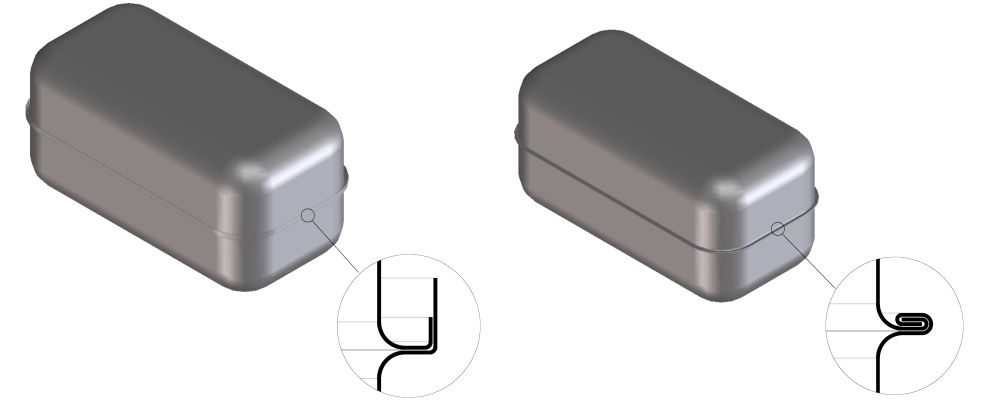

Production of rectangular boxes for various materials, consisting of container and lid.

LID

| Workpiece: | Deep drawn piece with flange |

| Material: | Normal Steel or Stainless Steel |

| Performed operation: | Edge Trimming - Braking of scrap into two parts in case workpiece is deep drawn with no flange (when necessary) |

| Working cycle: | Semi-Automatic |

BOX

| Workpiece: | Deep drawn piece with flange |

| Material: | Normal Steel or Stainless Steel |

| Performed operation: | Trimming - Beading |

| Working cycle: | Semi-Automatic |

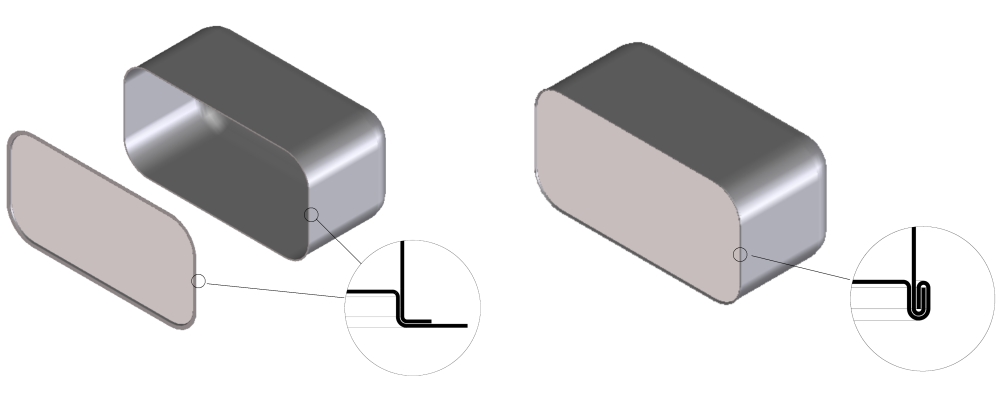

Production of rectangular tanks with intermediate joint for various liquids, consisting of male and female half-shells.

| Workpiece: | Deep drawn male and female pieces with shaped blank edge |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming (sealant coating when necessary) |

| Working cycle: | Semi-Automatic |

Production of rectangular tanks with joint on the base for various liquids, consisting of body and bottom end.

| Workpiece: | Body: deep drawn piece with blank flange; Bottom end: deep drawn piece with pre-curled blank flange |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic |

Production of tanks for spray gun bottles with various neck workings.

CURLED NECK

| Workpiece: | Deep drawn piece with narrowed trimmed neck |

| Material: | Aluminium |

| Performed operation: | Edge Deburring - outward Curling |

| Working cycle: | Semi-Automatic |

DOUBLE CURLED NECK

| Workpiece: | Deep drawn piece with narrowed trimmed neck |

| Material: | Aluminium |

| Performed operation: | Edge Deburring - outward Curling - curl Flattening |

| Working cycle: | Semi-Automatic |

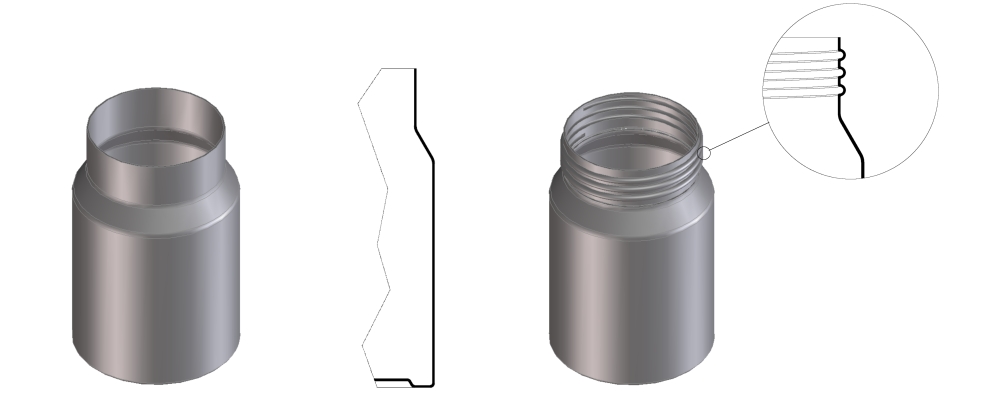

THREADED NECK

| Workpiece: | Deep drawn piece with narrowed trimmed neck |

| Material: | Aluminium |

| Performed operation: | Threading |

| Working cycle: | Semi-Automatic |

SOLUTIONS

Huile & Gaz

Bouteilles à gaz, réservoirs cylindriques et toroïdaux. Nos solutions vous permettent de produire des bouteilles de différentes tailles dans le même système, en optimisant les temps de configuration et la gestion du système, avec des avantages conséquents sur les performances et le temps de cycle.

Ventilation

Des bénéfices mesurables dans la technologie de l’outil et dans les automatisations utilisées qui permettent une réduction du nombre de passages impliquées dans le processus et une réduction des déchets, avec une réduction conséquente des coûts ainsi qu'une réduction des espaces de l'entrepôt industriel impliqué. Notre ligne automatique clé en main est en mesure de produire des conduits de ventilation tels que des raccords, des coudes, des réductions et des jonctions en T.

Batteries de cuisine

Nous proposons des solutions de production pour le développement de pots, couvercles, casseroles et plateaux qui permettent l'optimisation des opérations d'étirage, en régulant les vitesses, les forces et les courses du porte-flan et des extracteurs. Opérations particulièrement importantes lorsqu'il s'agit de matériaux tels que l'acier inoxydable ou les aciers multicouches, et lorsque l'on souhaite obtenir une qualité de la pièce réalisée sans défaut.

Appareils électroménagers

Nous concevons et développons des lignes clés en main pour éviers en acier inoxydable, hottes, pièces pour fours et plaques de cuisson, avec la possibilité de fournir des systèmes de changement automatique de table et de verrouillage de l’outil, une interface de ligne et une préparation de téléservice.

Chauffage et refroidissement

Nous sommes présents dans le monde entier avec des lignes de production clé en main pour la production de vases d'expansion, de chauffe-eau, de pompes à chaleur et de portes pour réfrigérateurs. Nous proposons des solutions de production avec un haut degré de flexibilité et avec la possibilité d'interconnexion au système d'usine.

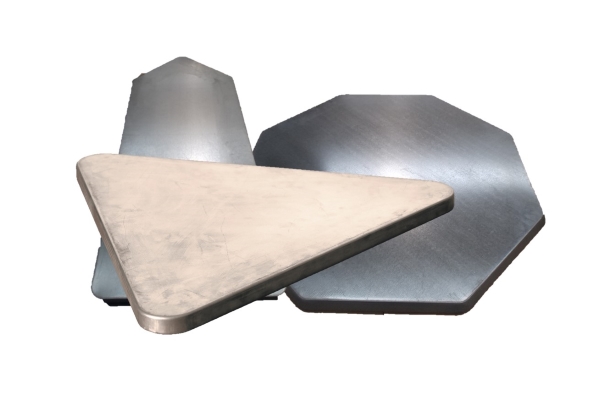

Panneaux routiers

Nous sommes présents sur le marché avec une production innovante de panneaux routiers polygonaux. À partir de la tôle prédécoupée, grâce à nos détoureuses-façonneuses CNC, un produit leader mondial, nous offrons la possibilité de réaliser des panneaux de signalisation en acier et en aluminium de toutes formes.