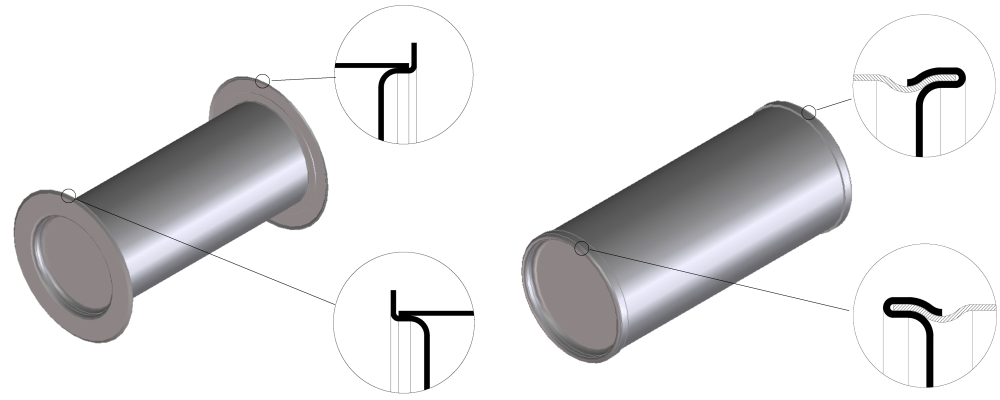

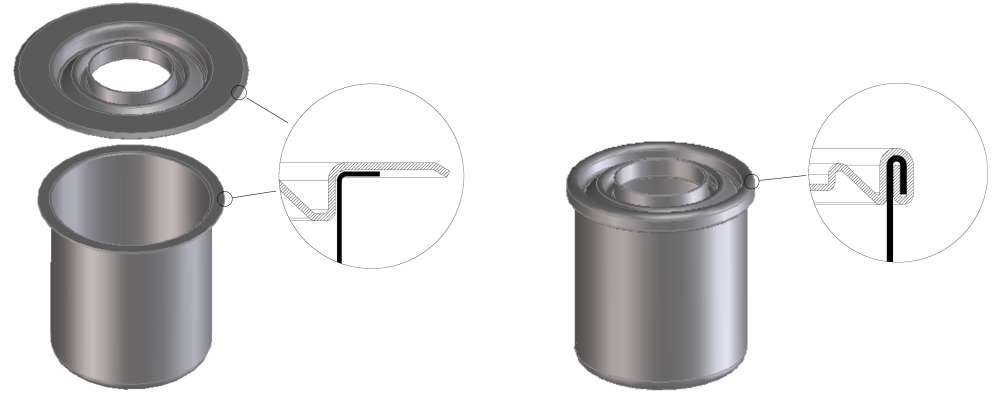

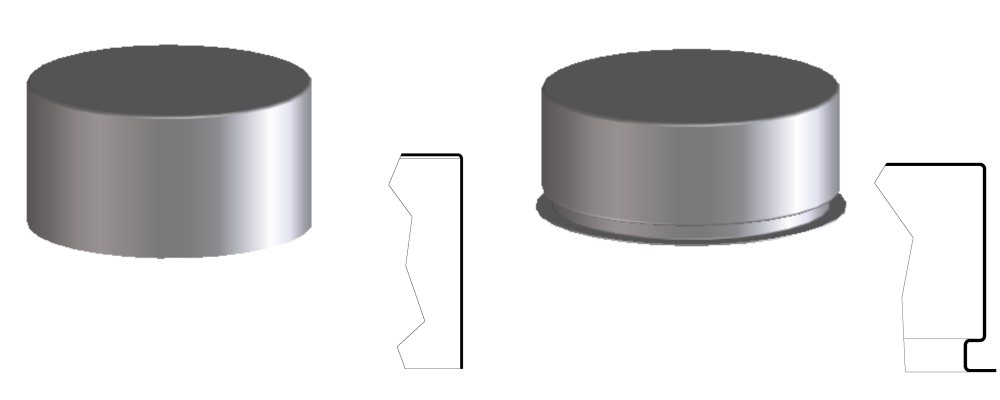

Preparation and assembly by caulking of supports for shock absorbers, consisting of bushing and flange.

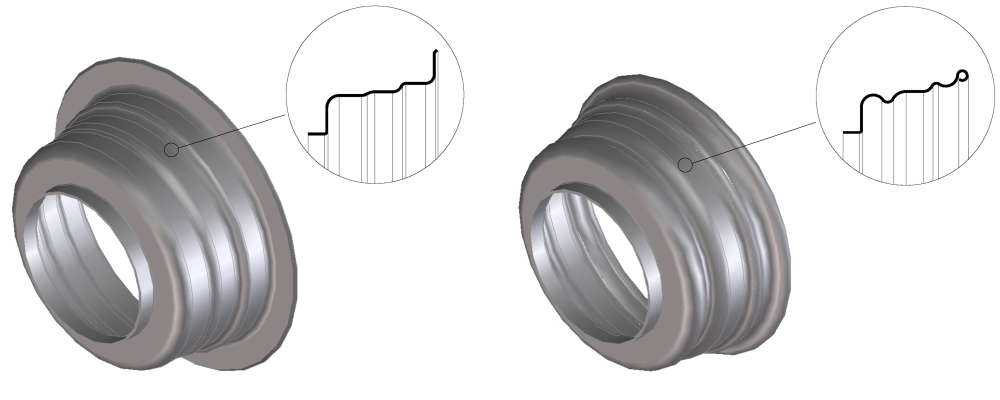

BUSH WORKING

| Workpiece: | Shaped deep drawn piece with blank flange |

| Material: | Normal steel |

| Performed operation: | Ribbing - Edge Curling |

| Working cycle: | Semi-Automatic |

ASSEMBLING PROCESS

| Workpiece: | Shaped deep drawn bush - shaped deep drawn flange |

| Material: | Normal steel |

| Performed operation: | Calking |

| Working cycle: | Semi-Automatic |

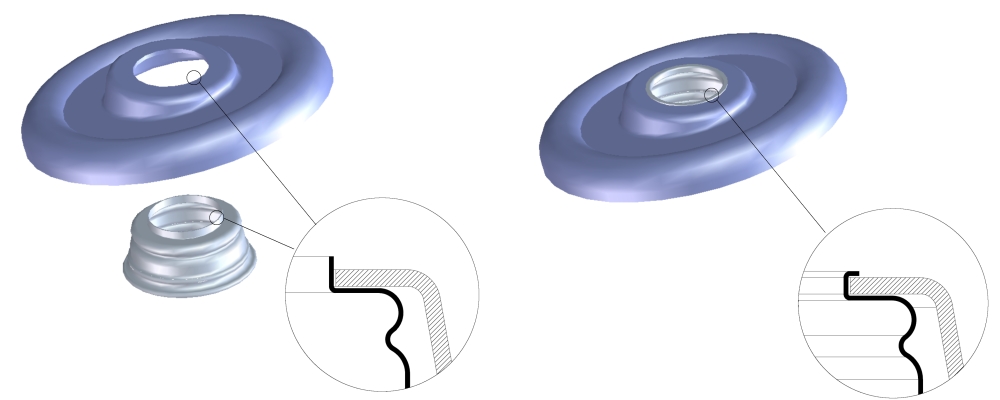

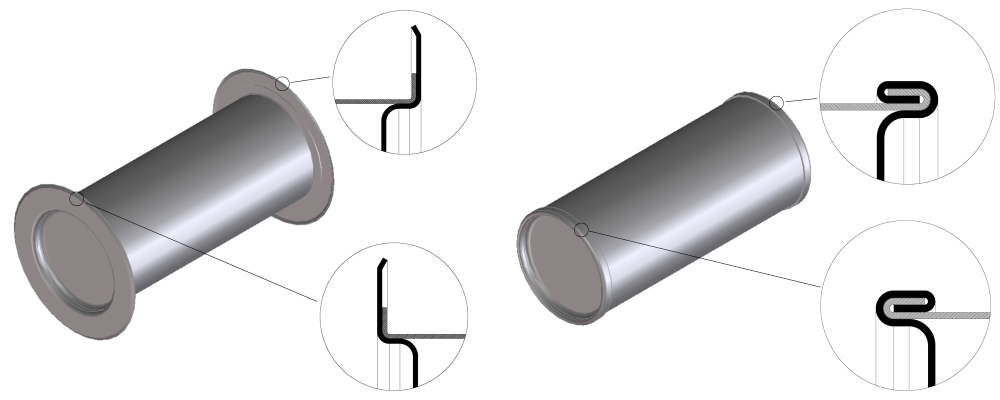

Assembly by caulking of protective elements for car joints, consisting of metal bushing and rubber casing.

| Workpiece: | Shaped deep drawn bush - shaped rubber casing |

| Material: | Normal steel - Rubber |

| Performed operation: | Calking of the two elements |

| Working cycle: | Semi-Automatic |

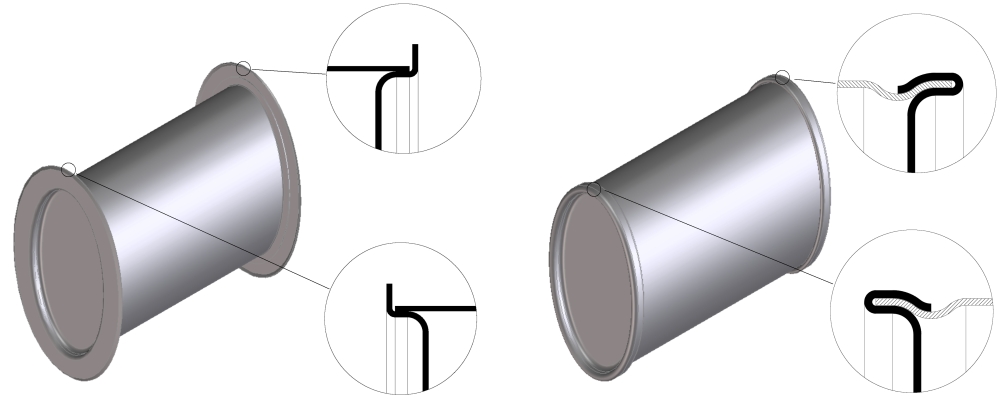

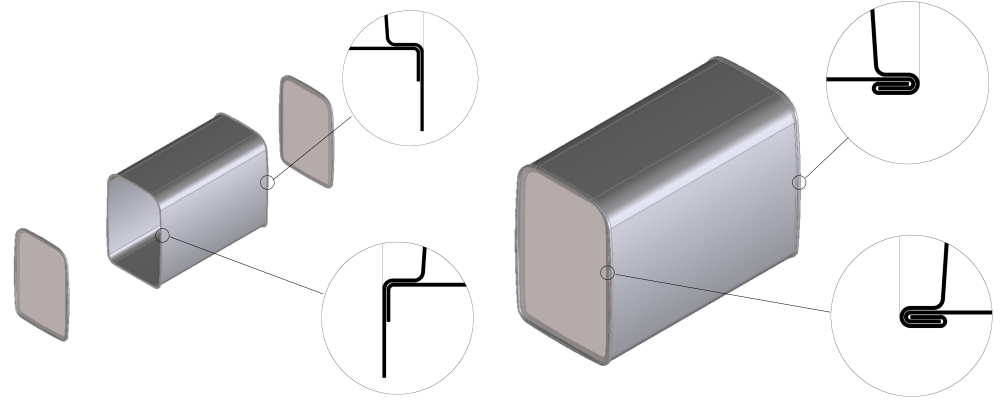

Assembly by 3- or 5-layer lockseaming of car silencers, consisting of body, two bottom ends and internal components.

5-LAYER LOCKSEAMING

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers and flanged ends; deep drawn bottom ends with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic, with two place settings to work in sequence both ends |

3-LAYER LOCKSEAMING

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers; deep drawn bottom ends with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | 3-layer Lockseaming |

| Working cycle: | Semi-Automatic, with two place settings to work in sequence both ends |

ONE PLACE SETTING SOLUTION

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers and/or flanged ends; deep drawn bottom ends with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming and/or simultaneous 3- or 5-layer Lockseaming of the ends |

| Working cycle: | Semi-Automatic, with one place setting, subject to the use of a two-head beading machine |

Assembly by 5-layer lockseaming of car silencers, consisting of body, two bottom ends and internal components.

| Workpiece: | Shaped tubular body with overlapping edges welded with pressure rollers; deep drawn bottom ends with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic, with two place settings to work in sequence both ends |

ONE PLACE SETTING SOLUTION

| Workpiece: | Shaped tubular body with overlapping edges welded with pressure rollers and flanged ends; deep drawn bottom ends with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - simultaneous 5-layer Lockseaming of the ends |

| Working cycle: | Semi-Automatic, with one place setting, subject to the use of a two-head beading machine |

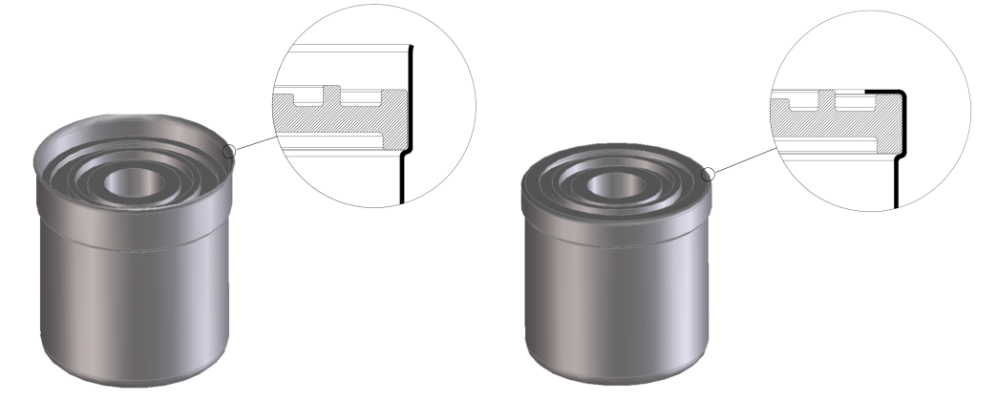

Assembly by caulking of oil filters for cars, consisting of deep drawn piece, aluminum bottom end and internal components.

| Workpiece: | Deep drawn piece with reducted flange; aluminium bottom end; inside components |

| Material: | Normal steel - Aluminium |

| Performed operation: | Caulking of the deep drawn edge onto the aluminium bottom end |

| Working cycle: | Semi-Automatic or Automatic, when included in a complete production line |

Assembly by 5-layer lockseaming of oil filters for cars, consisting of deep drawn piece, bottom end and internal components.

| Workpiece: | Deep drawn piece with blank flange; deep drawn bottom end with blank flange and pre-curling; inside components |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic or Automatic, when included in a complete production line |

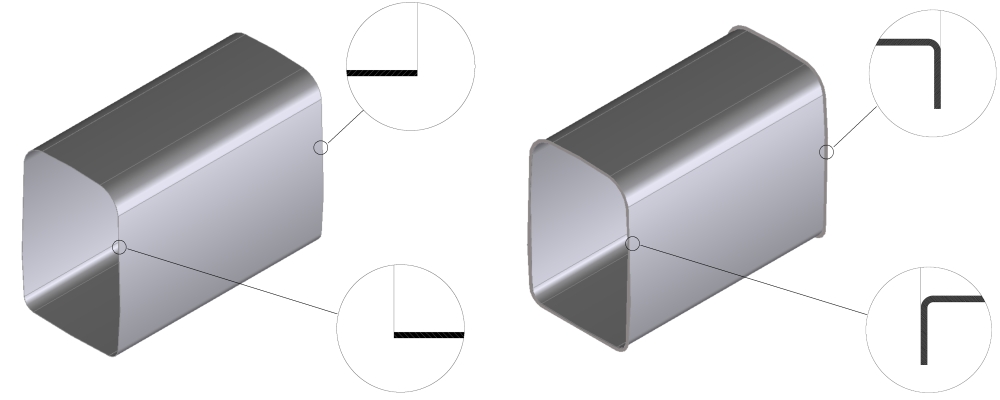

Preparation and assembly by 5-layer lockseaming of rectangular fuel tanks, consisting of body, two bottom ends and internal components.

BODY WORKING PROCESS

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers |

| Material: | Normal steel |

| Perfomed operation: | Outward Flanging |

| Working cycle: | Semi-Automatic, with two place settings to work in sequence both ends |

ASSEMBLING PROCESS

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers and with outward flanged edges |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - 5-layer Lockseaming |

| Working cycle: | Semi-Automatic, with two place settings to work in sequence both ends |

ONE PLACE SETTING SOLUTION

| Workpiece: | Shaped body with overlapping edges welded with pressure rollers and with outward flanged edges |

| Material: | Normal steel |

| Performed operation: | Pre-Lockseaming - simultaneous 5-layer Lockseaming on both edges |

| Working cycle: | Semi-Automatic with one place setting, subject to the use of a two-head beading machine |

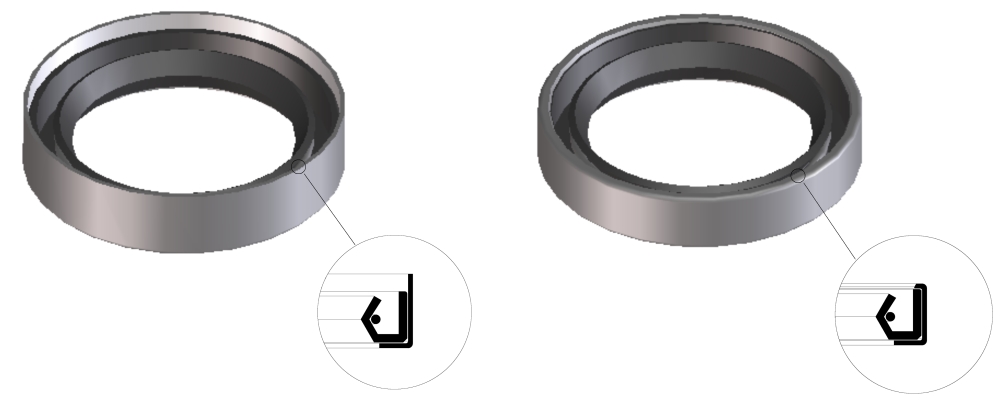

Assembly and finishing of sealing rings for rotating shafts, consisting of metal ring and seal.

| Workpiece: | Shaped deep drawn ring - Seal |

| Material: | Normal steel - Rubber |

| Performed operation: | Edge Chamfering - Calking of the two components - outer diameter Turning |

| Working cycle: | Semi-Automatic |

Production of casings for pressure gauges.

| Workpiece: | Deep drawn piece with reduced flange |

| Material: | Stainless Steel |

| Performed operation: | Trimming - Ribbing - edge outward Flanging |

| Working cycle: | Semi-Automatic |

SOLUTIONS

Huile & Gaz

Bouteilles à gaz, réservoirs cylindriques et toroïdaux. Nos solutions vous permettent de produire des bouteilles de différentes tailles dans le même système, en optimisant les temps de configuration et la gestion du système, avec des avantages conséquents sur les performances et le temps de cycle.

Ventilation

Des bénéfices mesurables dans la technologie de l’outil et dans les automatisations utilisées qui permettent une réduction du nombre de passages impliquées dans le processus et une réduction des déchets, avec une réduction conséquente des coûts ainsi qu'une réduction des espaces de l'entrepôt industriel impliqué. Notre ligne automatique clé en main est en mesure de produire des conduits de ventilation tels que des raccords, des coudes, des réductions et des jonctions en T.

Batteries de cuisine

Nous proposons des solutions de production pour le développement de pots, couvercles, casseroles et plateaux qui permettent l'optimisation des opérations d'étirage, en régulant les vitesses, les forces et les courses du porte-flan et des extracteurs. Opérations particulièrement importantes lorsqu'il s'agit de matériaux tels que l'acier inoxydable ou les aciers multicouches, et lorsque l'on souhaite obtenir une qualité de la pièce réalisée sans défaut.

Appareils électroménagers

Nous concevons et développons des lignes clés en main pour éviers en acier inoxydable, hottes, pièces pour fours et plaques de cuisson, avec la possibilité de fournir des systèmes de changement automatique de table et de verrouillage de l’outil, une interface de ligne et une préparation de téléservice.

Chauffage et refroidissement

Nous sommes présents dans le monde entier avec des lignes de production clé en main pour la production de vases d'expansion, de chauffe-eau, de pompes à chaleur et de portes pour réfrigérateurs. Nous proposons des solutions de production avec un haut degré de flexibilité et avec la possibilité d'interconnexion au système d'usine.

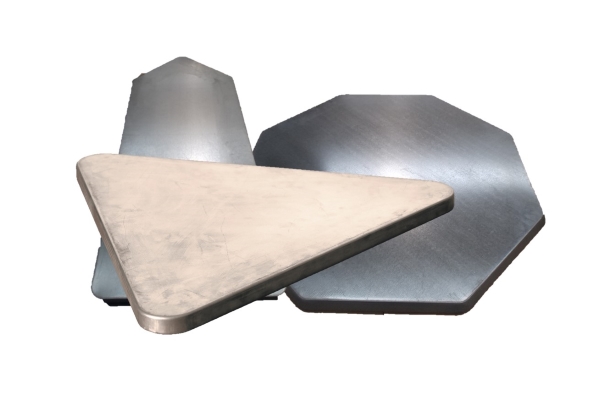

Panneaux routiers

Nous sommes présents sur le marché avec une production innovante de panneaux routiers polygonaux. À partir de la tôle prédécoupée, grâce à nos détoureuses-façonneuses CNC, un produit leader mondial, nous offrons la possibilité de réaliser des panneaux de signalisation en acier et en aluminium de toutes formes.