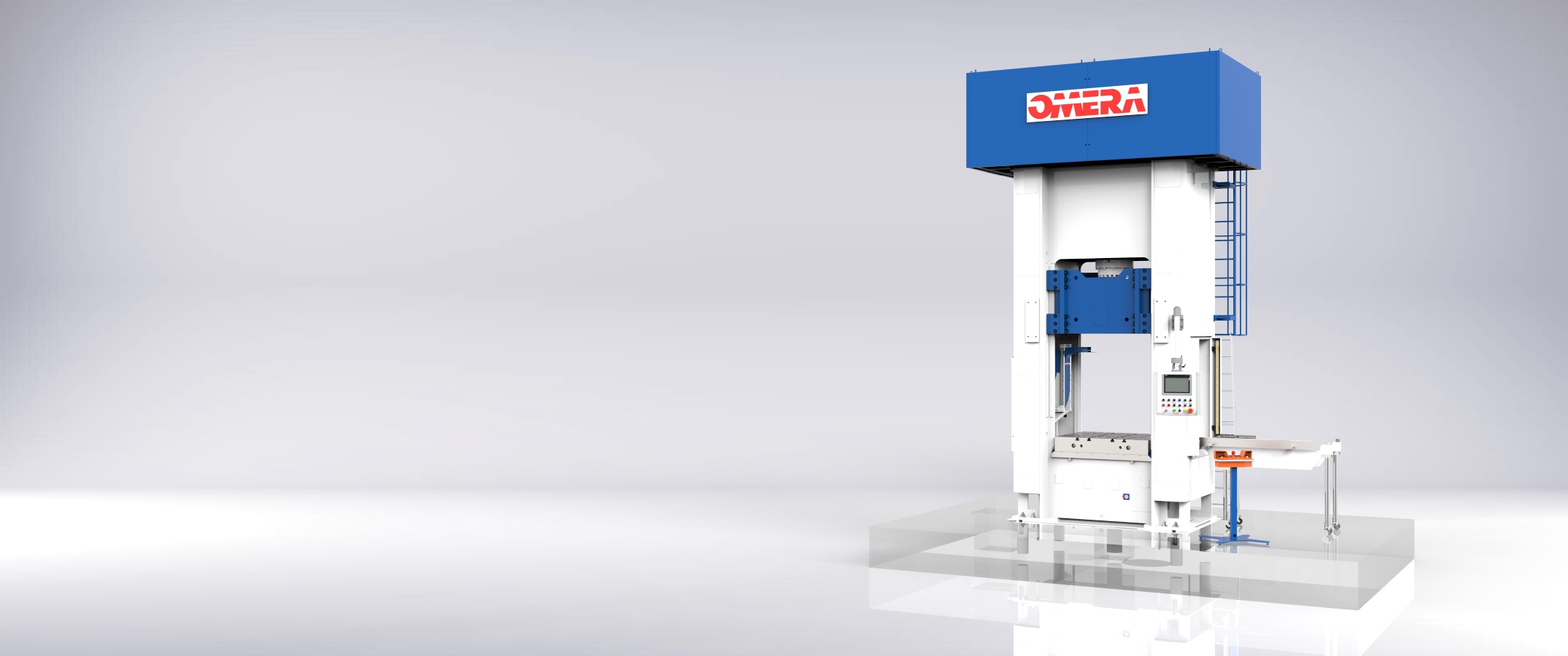

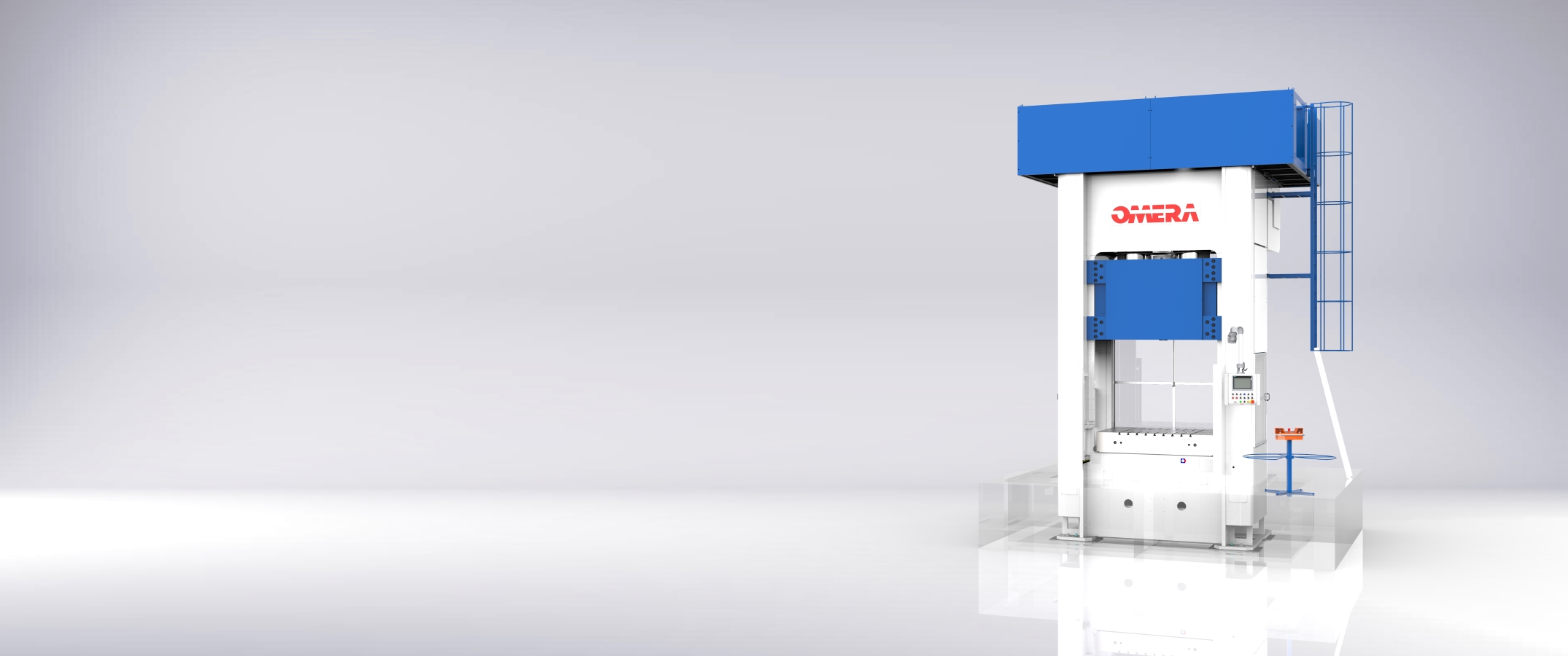

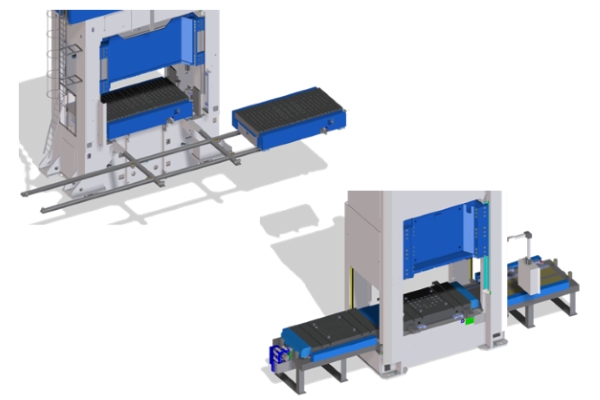

The monolithic or composite press is widely used in a vast range of applications in a whole host of different industrial sectors involving sheet metal working. Hydraulic presses can be supplied complete with dies and automatic feeding systems and are typically used in the production of:

- Bottom ends for water heaters and tanks

- Cooker tops

- Domestic appliances

- Drinks containers

- Stainless steel pots and pans

- Pressurised containers

- Gas cylinders

- Fire extinguishers

- Automotive parts